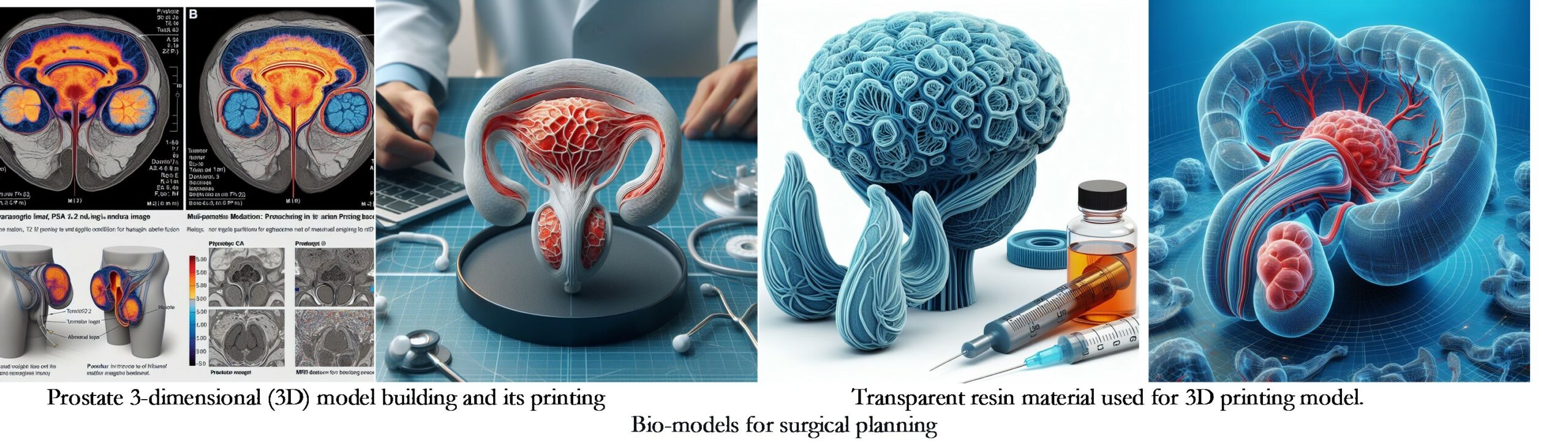

Bio-models for surgical planning (BM-PQ)

Next, there are some guidelines for medical and individualized cases with their coding, obtained after analyzing the respective references, and grouped by case study and common trends, highlighting in bold the competitive advantages that can become innovations.

BM-PQ-01. The digital models based on which the simulator is designed can be extracted from patient-specific computed tomography (CT) or magnetic resonance imaging (MRI) scans or digital libraries [1], [2].

BM-PQ-02. A minimum layer height of 0.1mm should be used to print bio models. The accuracy and resolution required for surgical planning are high [1], [2].

BM-PQ-03. Suppose the process does not handle the material with the required strength, color, or other properties. In that case, the FFF process can be used indirectly, by printing the model to make the mold or directly printing the mold, so that the use of FFF is not restricted only to available materials but is extended with the possibilities of other processes such as casting and molding [1], [2].

BM-PQ-04. Because full-color organ models are required to identify and plan the surgery or operation properly, the options for using FFF should be: Design the assembly and print each part in a different color; use the printer with several extruders, one for each color; or paint the parts [1], [2].

BM-PQ-05. Cardiologists must have the model printed before surgery, so waiting times should be moderate. AM successfully produces low-cost models for implants or medical models compared to machining [1], [2].

Please refer to the original bibliographic references or consult the References database or Medical database for more details.

References

[1] Y. Wang et al., “Three-dimensional printing technique assisted cognitive fusion in targeted prostate biopsy,” Asian J. Urol., vol. 2, no. 4, pp. 214–219, Oct. 2015.

[2] A. Haleem, M. Javaid, and A. Saxena, “Additive manufacturing applications in cardiology: A review,” Egypt. Hear. J., vol. 70, no. 4, pp. 433–441, 2018.