Production rates, size & feature limitations, material constraints.

Here are the summarized general rules (RG) of design, categorized by common topics. The competitive and innovative advantages are highlighted in bold, and their application is illustrated with Figures or Tables.

RG-CP-01. Redesign a consolidated part in an assembly of several parts to be consolidated or not later; It will Improve the production rates, size feature limitations, and material constraints.

For example, improve production rates and size: Reduce the volume of each part and print on one or more printers in series or parallel with manufacturing parameters that take advantage of the benefits of the FFF process.

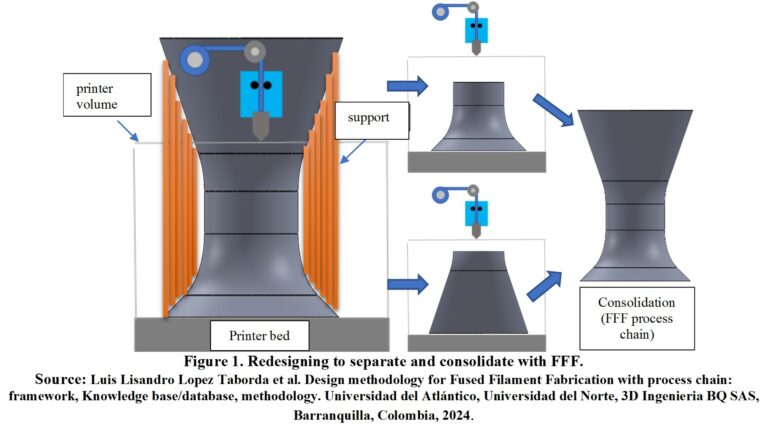

Figure 1 on the left side demonstrates a case where the part’s size exceeds the available printer capacity, necessitating support material and resulting in increased material consumption and longer manufacturing times.

However, on the right side of the figure 1, the part is divided into two smaller components that can be printed individually without the need for support material.

By consolidating these smaller parts after printing, the surface finish can be improved while minimizing the amount of support material required, thus reducing manufacturing time.

RG-CP-02. Manufacturing indirectly with FFF to support other processes with better production rate, better tolerances, and finishes, or better biocompatibility depending on the case: Plastic injection, plastic blow molding, hydroforming, laser cutting and thermoforming, silicone mold casting, sand mold casting, inverted casting, among others.

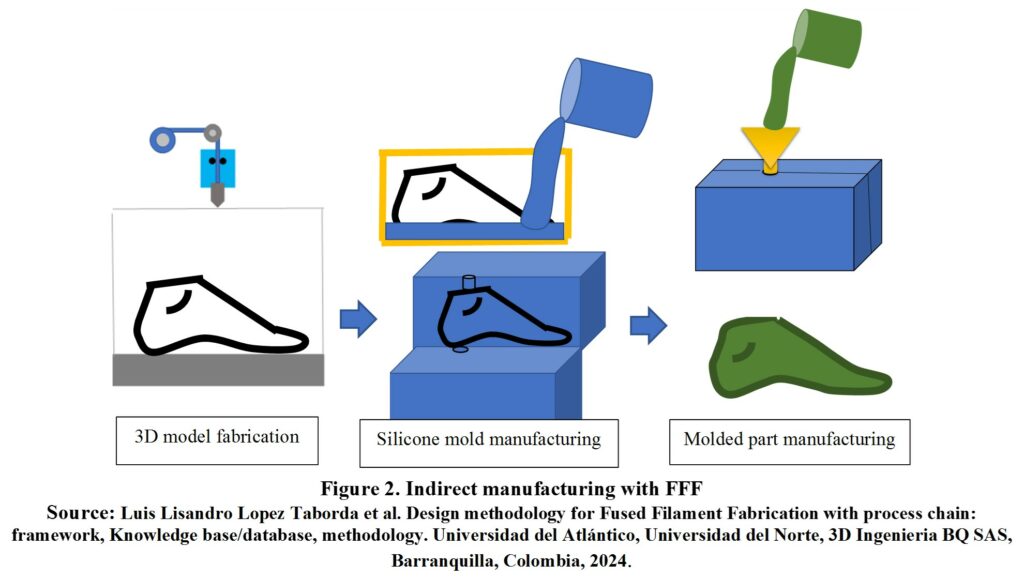

Figure 2 illustrates the manufacturing of prosthetic foot.

The production rate of FFF or FDM is low. However, by using the printed model to create a silicone mold and the mold to manufacture the final part, for example, silicon or resin, the manufacturing process achieves higher production rates than the printed process.

Moreover, the molded parts exhibit superior surface finish and mechanical properties compared to printed materials. For instance, the silicone prosthetic foot offers enhanced flexibility, while the epoxy resin prosthetic foot provides increased mechanical strength.

RG-CP-03. Achieve low-resolution features using other subsequent processes: machining or micromachining.

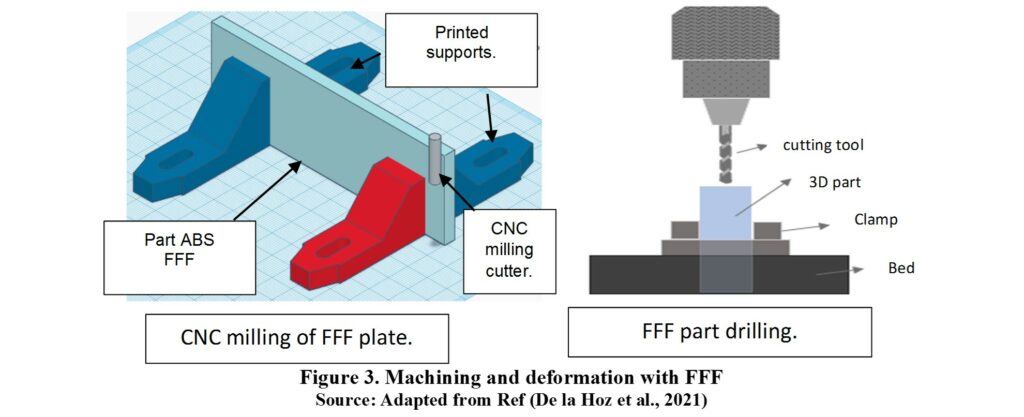

Figure 3 shows that the printed parts are subsequently machined on a CNC milling machine or conventional drill.

In this way, small features can be machined that would not be possible with the printed process, but they can be machined within the ranges, tolerances, and finishes of conventional machining processes.