Personalization for medical applications and individualization.

Here are the summarized general rules (RG) of design, categorized by common topics. The competitive and innovative advantages are highlighted in bold, and their application is illustrated with Figures or Tables.

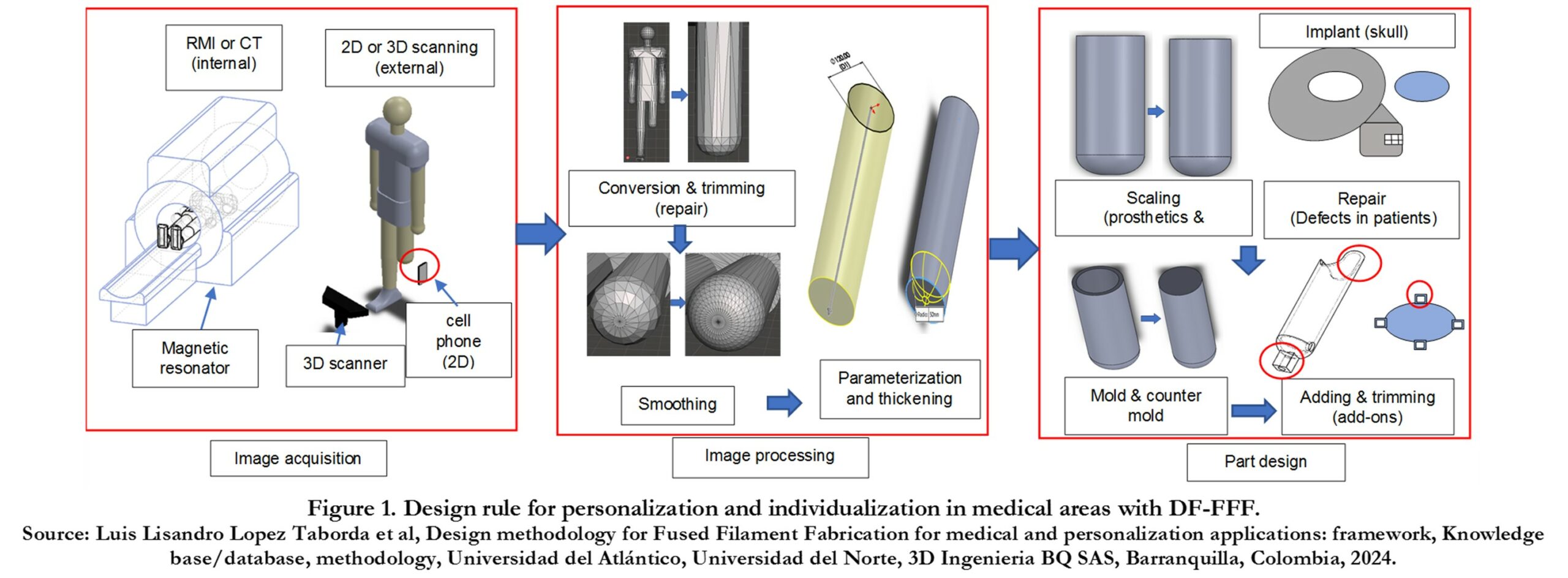

RG-ME-01. Incorporate image information of the patient or client into the design. This involves capturing images through medical imaging or scans. Digital information undergoes two stages of modification: image processing and product design [1].

- Image processing includes converting the information to digital surfaces, trimming, smoothing textures, and parameterization [1].

- Product design varies depending on the specific case and includes scaling, defect repair, blending, mold creation, trimming, and additions [1].

Careful selection of software for this process, favoring specialized applications, positively impacts the final product design time and cost [1].

Figure 1 depicts the use of image information for designing custom prosthetic sockets and bone implants.

Figure 1 shows three stages: image acquisition, image processing/conversion, and design modification. Differentiating between 3D scanners or 2D scanners with cell phones for external features and MRI or CT for internal features [1].

Digital image integration streamlines the process, reducing steps, time, waste, and costs associated with traditional mold-based measurements. This optimization improves efficiency and accelerates delivery times [1].

References

[1] Luis Lisandro Lopez Taborda et al, Design methodology for Fused Filament Fabrication for medical and personalization applications: framework, Knowledge base/database, methodology, Universidad del Atlántico, Universidad del Norte, 3D Ingenieria BQ SAS, Barranquilla, Colombia, 2024.