Parametric personalization and individualization (PP&I)

Next, there are some guidelines for medical and individualized cases with their coding, obtained after analyzing the respective references, and grouped by case study and common trends, highlighting in bold the competitive advantages that can become innovations.

PP&I-01. Utilize online platforms for customer interaction, offering preset options for design and color selection, as well as order management. [1]–[4].

This approach reduces visits and turnaround times.

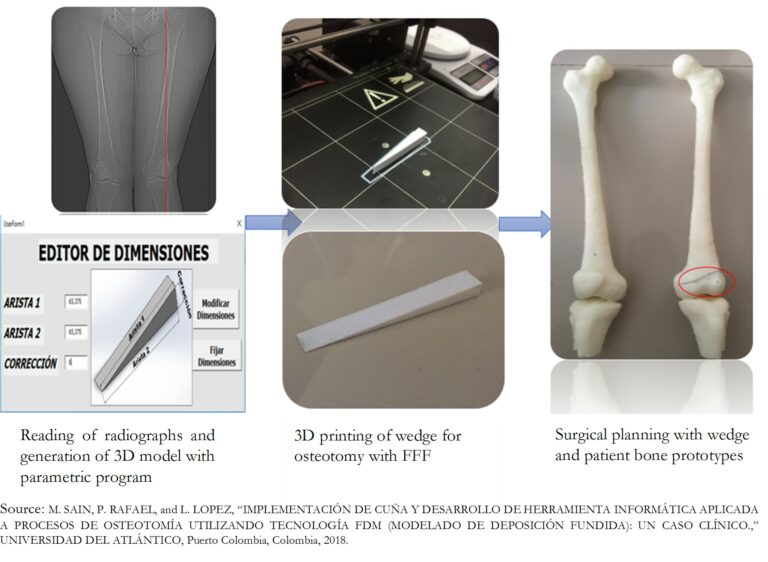

PP&I-02. To parameterize a customized design, it is recommended to interview physicians and patients, inquire about medical criteria, and synthesize the relevant measurements controlling the design’s function. Relevant measurements can be obtained by reading patient images, and a program can automatically generate the geometric design by inserting these measurements. [5].

This parameterization process, based on inquiries with healthcare professionals, patients, and clients, enhances customization, individualization, and reduces modeling time.

PP&I-03. Use parametric designs available online so that the customer can modify and customize as desired [4], [6].

PP&I-04. Divide the product into a standardized module, manufactured with conventional materials and processes that are more competitive when mass-produced, and another interchangeable module, either by an individualized part manufactured by AM or a standardized one manufactured conventionally. In this way, the customer has the freedom to choose between a completely standardized and economical product or a standardized and individualized product with his measurements and preferences and with higher added value [7], [1], [2], [8].

PP&I-05. Use online programs such as cell phone applications and 3D scanners from local partners to remotely capture customer measurements and other qualities and incorporate them into the design, reducing time and number of trips [[7], [1], [2], [8], [3].

PP&I-06. Customer comfort can be achieved by multi-material or internal multi-pattern printing, achieving rigid and soft zones depending on patient sensitivity and contact areas, or cushioning requirements [7], [1], [2], [8].

PP&I-07. For implants, local requirements and standards must be met; for example, in the case of throat stents, ISO 10993-1, FDA-approved for long-term implantation, The material must have thermal stability at 35-45 °C. ISO 10993-18:2005: Chemical stability must not react with the environment (air, body cells, blood) [5].

PP&I-08. Stiffness must be determined by the surrounding tissues in contact with the product [5].

PP&I-09. To use an online database to consult solutions and get inspiration. The recommended online database to inspire an integrated solution is Thingiverse, which contains 1.6 million individual designs with statistics on the number of prints and downloads. The inspiration for the solution can be the product of several designs or a single design combining several (remix). Each design in the database is an alternative to be selected within the design process [6].

PP&I-10. Consider the solution as a remix. Community members print most of the designs created by remixing. Designers optimize products concerning functional attributes and, in turn, make them more “printable.” This higher print rate improves remixing by focusing design on productivity. Designers rely on existing solutions to achieve the desired result [6].

Please refer to the original bibliographic references or consult the References database or Medical database for more details.

References

[1] “Heroes Sandals,” 2021. [Online]. Available: https://www.heroessandals.com/howtomeasure.

[2] “Footb 3D TM,” 2021. [Online]. Available: https://casca.com/products/footb3d-custom-insole.

[3] “Custom 3D Printed Glasses,” 2021. [Online]. Available: https://home.specsy.com/.

[4] “custom-made-3d-printed-glasses.” 2021.

[5] E. L. Melgoza, L. Sereno, A. Rosell, and J. Ciurana, “An integrated parameterized tool for designing a customized tracheal stent,” Comput. Des., vol. 44, no. 12, pp. 1173–1181, 2012.

[6] S. Friesike, C. M. Flath, M. Wirth, and F. Thiesse, “Creativity and productivity in product design for additive manufacturing: Mechanisms and platform outcomes of remixing,” J. Oper. Manag., 2018.

[7] Q. STUDIO, “THE EARTH SHOE.” .

[8] wiivv.com, “PLANTILLAS PERSONALIZADAS DE WIIVV.” .