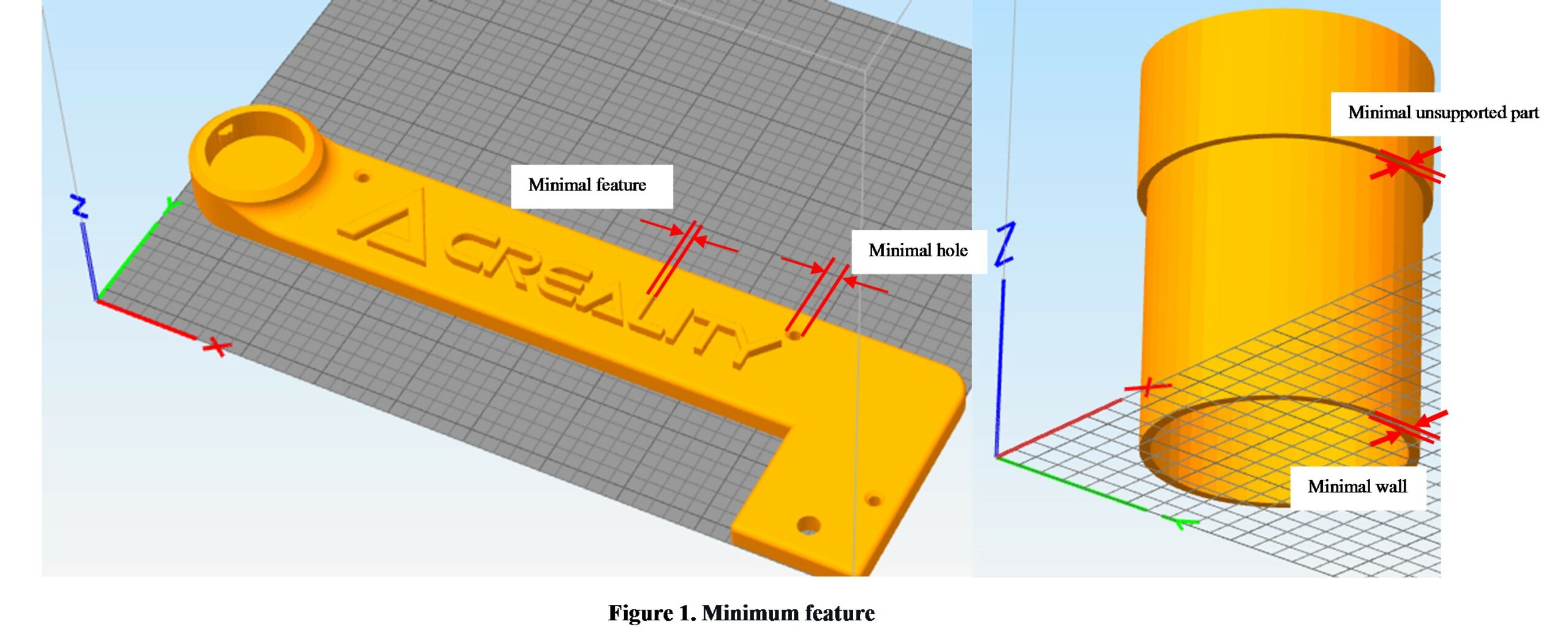

Minimum feature

It refers to the minor features or details that can be fabricated and the rules or recommendations for fabricating those small features using FFF or FDM. Below are some recommendations.

- Below 0.4mm clearances or grooves, precision is lost. Also, protrusions or air gaps up to 1.8mm in length can be fabricated without support but be careful with radii below 2.0mm (FDM) [1], [2].

- FDM requires a minimum wall thickness of 1.5mm. Holes can have radii up to 4.5mm without support; above that, the arches deteriorate [3].

- Wall thicknesses greater than 3mm are recommended (but a minimum of 1.5mm does not rule out the process) [4].

- The minimum wall thicknesses that can be manufactured with FDM are a function of layer height: for a 0.71mm wall, the layer is 0.18mm [2].

- In the case of continuous-release drug design, fitting details are 2mm, capsule wall up to 1mm, and holes are 1.5mm to 2mm [5].

- Channel distances ranging from 78 μm to 1482 μm (0.078-1.482mm), interconnected pores, and pore sizes between 300-600 um (0.3-0.6mm) in an indirect scaffold manufacturing process using FFF/FDM as the Mold [6].

Generally, small features require setting the layer height to small values and small nozzle diameters. However, it reduces manufacturing times.

If you want to increase production rates while maintaining or reducing minimum features, you can combine the FFF process at high speeds, large layer heights, or nozzle sizes with machining. However, due to the inclusion of additional processes in FFF, it is recommended that you consult the Process Chain page.

References

[1] G. A. O. Adam and D. Zimmer, “Design for Additive Manufacturing{\textemdash}Element transitions and aggregated structures,” {CIRP} J. Manuf. Sci. Technol., vol. 7, no. 1, pp. 20–28, 2014.

[2] H. I. Medellin-Castillo and J. Zaragoza-Siqueiros, “Design and Manufacturing Strategies for Fused Deposition Modelling in Additive Manufacturing: A Review,” Chinese J. Mech. Eng., vol. 32, no. 1, Jun. 2019.

[3] G. A. O. Adam and D. Zimmer, “On design for additive manufacturing: evaluating geometrical limitations,” Rapid Prototyp. J., vol. 21, no. 6, pp. 662–670, Oct. 2015.

[4] J. W. Booth, J. Alperovich, P. Chawla, J. Ma, T. N. Reid, and K. Ramani, “The Design for Additive Manufacturing Worksheet,” J. Mech. Des., vol. 139, no. 10, p. 100904, 2017.

[5] S. H. Lim, S. M. Y. Chia, L. Kang, and K. Y.-L. Yap, “Three-Dimensional Printing of Carbamazepine Sustained-Release Scaffold,” J. Pharm. Sci., vol. 105, no. 7, pp. 2155–2163, Jul. 2016.

[6] S. Mohanty et al., “Fabrication of scalable tissue engineering scaffolds with dual-pore microarchitecture by combining 3D printing and particle leaching,” Mater. Sci. Eng. C, vol. 61, pp. 180–189, 2016.