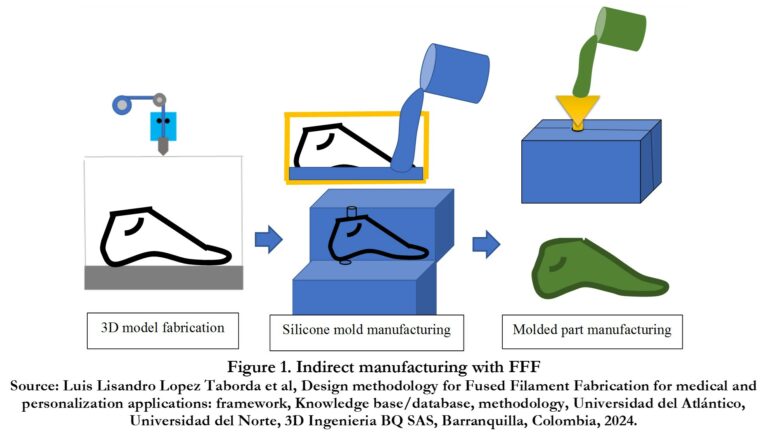

Indirect manufacturing with FFF.

Here are the summarized general rules (RG) of design, categorized by common topics. The competitive and innovative advantages are highlighted in bold, and their application is illustrated with Figures or Tables.

RG-ME-05. Manufacturing indirectly with FFF to support other processes with better mechanical strength, biocompatibility, color, or hardness depending on the specified case, for example, silicone mold casting.

Figure 1 illustrates the manufacturing of prosthetic foot.

By using the printed model to create a silicone or resin mold and the mold to manufacture more flexible end part, the manufacturing process achieves higher damping properties than the printed process like PA o TPU.

The biocompatibility of printed FFF materials and other aspects, such as mechanical strength, is low compared to conventional processes. Using FFF to support other processes with more biocompatible or more robust materials extends the original limitations of the FFF process.

This practice is especially advantageous in applications where biocompatibility is more critical, such as internal permanent implants, or where mechanical strength is especially critical, such as lower limb orthoses and prostheses.

References

[1] Luis Lisandro Lopez Taborda et al, Design methodology for Fused Filament Fabrication for medical and personalization applications: framework, Knowledge base/database, methodology, Universidad del Atlántico, Universidad del Norte, 3D Ingenieria BQ SAS, Barranquilla, Colombia, 2024.