Indirect Manufacturing and others

The following summarizes some guidelines for coded FFF process chain (CP) cases with their respective references.

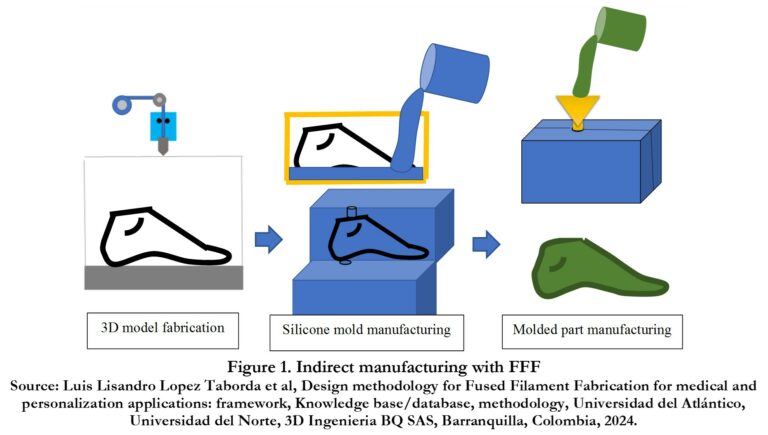

CP-08. Indirect manufacturing (example, molding with printed mold like Figure 4) should be used to expand the possibilities of FFF, both in terms of materials and processes, applications, and uses, while increasing strength, reducing manufacturing times and costs, reducing tolerances and fits, reducing roughness and reducing the weight of parts, among other competitive advantages [21], [22], [23], [24], [15], [25], [26], [27], [28], [29], [30], [31], [32], [33], [34].

For more guidelines using FFF process chain, go to the database.

Other Improvements

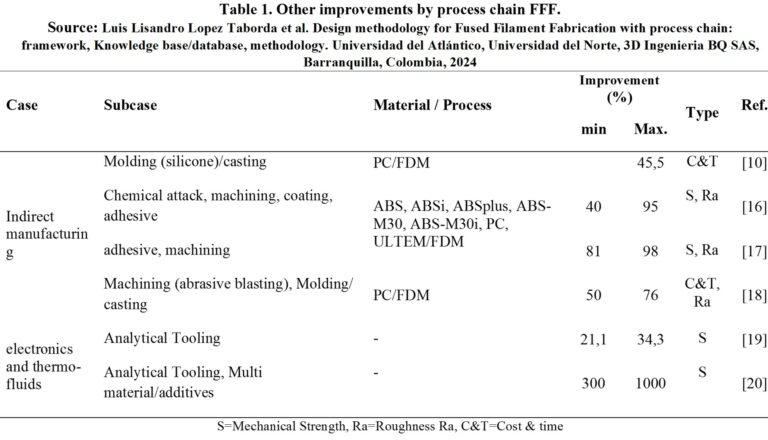

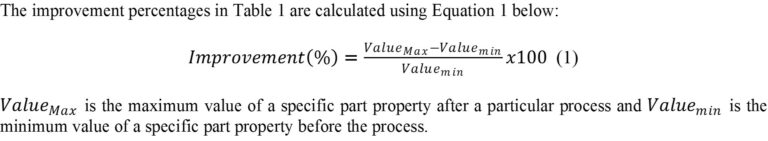

During the case analysis, improvements in properties such as tolerances, roughness, mechanical strength, and times/costs were identified through the combination of FFF or FDM with conventional processes. Table 1 provides a partial overview of the results obtained specifically for the assembly and others case.

To interpret the findings in Table 1, an example is provided:

- The maximal improvement in cost and time (C&T) is 76% associated to Machining (abrasive blasting), Molding/casting [18]. The improvement values are presented as ranges (min and max), because the specific values depend on the interaction of FFF processing factors and conventional manufacturing.

To use the figures in Table 1 or the process chain database, from which these figures are derived, when designing a product, one should:

a) To know in advance what properties or specifications the product being designed should have, and in that case, to determine which process combination achieves the desired properties.

b) On the other hand, in the case of redesigning parts manufactured with FFF, whose properties are not by the desired specifications, the same table indicates the percentages of improvement possible by combining FFF with other specific processes; in this case, the processes that achieve the required improvements for the application to be designed are identified.

c) Once the possible processes or processes have been identified, the process chain database must be consulted to consult how the processes and their parameters are combined with FFF and print parameters.

d) The same database also contains process costs and times and the health and environmental impacts of using additional materials. This information will allow making objective decisions about the properties and costs associated with combining other materials and processes.

e) any details to expand or clarify can be read directly in the coded bibliographic reference.

The handling for other properties, such as tolerances, mechanical properties, assembly, and others, is similar.

References

[1] C. C. Ploch, C. S. S. A. Mansi, J. Jayamohan, and E. Kuhl, “Using 3D Printing to Create Personalized Brain Models for Neurosurgical Training and Preoperative Planning,” World Neurosurg., vol. 90, pp. 668–674, Jun. 2016.

[2] O. C. Burdall, E. Makin, M. Davenport, and N. Ade-Ajayi, “3D printing to simulate laparoscopic choledochal surgery,” J. Pediatr. Surg., vol. 51, no. 5, pp. 828–831, May 2016.

[3] Stratasys, “TECHNICAL APPLICATION GUIDE: Silicone Molding With FDM Patterns.” 2015.

[4] Y. He, G. Xue, and J. Fu, “Fabrication of low cost soft tissue prostheses with the desktop 3D printer,” Sci. Rep., vol. 4, no. 1, Nov. 2014.

[5] Stratasys, FDM for Composite Tooling. Stratasys, 2017.

[6] M. Chhabra and R. Singh, “Rapid casting solutions: a review,” Rapid Prototyp. J., vol. 17, no. 5, pp. 328–350, 2011.

[7] S. Singh and R. Singh, “Fused deposition modelling based rapid patterns for investment casting applications: a review,” Rapid Prototyp. J., vol. 22, no. 1, pp. 123–143, 2016.

[8] Stratasys, “APPLICATION GUIDE: Thermoforming.” 2015.

[9] M. HÉCTOR, A. ORTIZ, and L. LOPEZ, “DISEÑO Y CONSTRUCCIÓN DE PROTOTIPO DE MOLDE PARA RECONSTRUCCIÓN ÓSEA A PARTIR DE TOMOGRAFÍA COMPUTARIZADA MEDIANTE IMPRESIÓN 3D,” UNIVERSIDAD DEL ATLÁNTICO, FACULTAD DE INGENIERÍA, DEPARTAMENTO DE INGENIERÍA, PROGRAMA DE INGENIERÍA MECÁNICA, Puerto Colombia – Atlántico, COLOMBIA, 2021.

[10] L. Ruiz-Huerta, Y. C. Almanza-Arjona, A. Caballero-Ruiz, H. A. Castro-Espinosa, C. M. D\’\iaz-Aguirre, and E. E. y Pérez, “{CAD} and {AM}-fabricated moulds for fast cranio-maxillofacial implants manufacture,” Rapid Prototyp. J., vol. 22, no. 1, pp. 31–39, 2016.

[11] P. A. Thomas, P. K. Aahlada, N. S. Kiran, and J. Ivvala, “A Review On Transition In The Manufacturing Of Mechanical Components From Conventional Techniques To Rapid Casting Using Rapid Prototyping,” Mater. Today Proc., vol. 5, no. 5, pp. 11990–12002, 2018.

[12] O. Abdelaal, S. Darwish, K. A. Elmougoud, and S. Aldahash, “A new methodology for design and manufacturing of a customized silicone partial foot prosthesis using indirect additive manufacturing,” Int. J. Artif. Organs, vol. 42, no. 11, pp. 645–657, 2019.

[13] Stratasys, “TECHNICAL APPLICATION GUIDE FDM Tooling for Sheet Metal Forming: Hydroforming and Rubber Pad Press.” 2015.

[14] Stratasys, “TECHNICAL APPLICATION GUIDE: FDM FOR SAND CASTING.” 2013.

[15] Stratasys, “TECHNICAL APPLICATION GUIDE: Investment Casting with FDM Patterns.” 2015.

[16] Stratasys, “TECHNICAL APPLICATION GUIDE: FDM For Jigs And Fixtures.” 2015.

[17] Stratasys, “TECHNICAL APPLICATION GUIDE: Paper Pulp Molding with FDM Tooling.” 2015.

[18] Stratasys, “APPLICATION GUIDE: Injection Blow Molding with FDM.” 2015.

[19] R. Hu et al., “Design Optimization Method for Additive Manufacturing of the Primary Mirror of a Large-Aperture Space Telescope,” J. Aerosp. Eng., vol. 30, no. 3, p. 4016093, May 2017.

[20] A. Takezawa and M. Kobashi, “Design methodology for porous composites with tunable thermal expansion produced by multi-material topology optimization and additive manufacturing,” Compos. Part B Eng., vol. 131, pp. 21–29, 2017.