Fracture Failure Theory

The following is a summary of codified guidelines for failure theory (TEFA) based on the analysis of the accuracy and requirements of models used to predict the failure of materials manufactured by FFF or FDM, highlighting in bold the accuracy of the models as a measure of the degree of reliability of the products

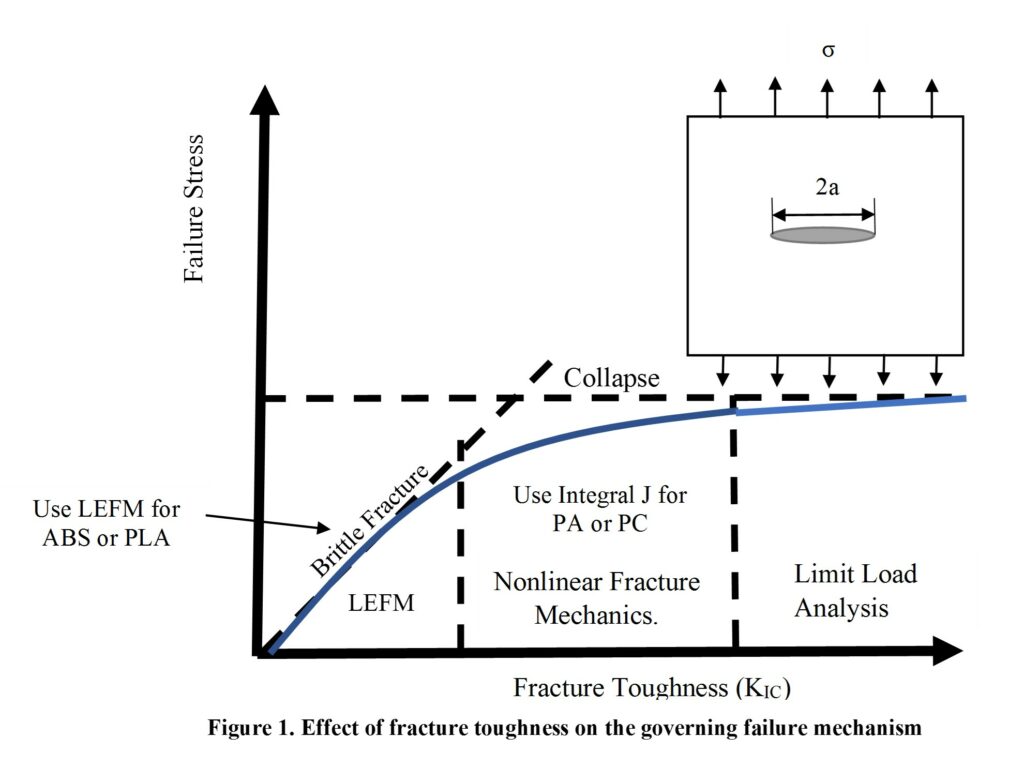

TEFA-10. To predict fracture failure and crack propagation in printed parts, use linear elastic theory for brittle materials such as ABS or PLA and J-integral for ductile materials such as PC or Nylon (PA).

In the field of fracture mechanics, a clear distinction is observed between ductile materials in which PC and PA are classified [1], [2] and brittle materials such as ABS [83]. Among the models, the J-integral is used for ductile materials, and the linear elastic theory for brittle materials.

The error percentages average from 7% for ductile to 20% for Nylon and between 4% and 30% for brittle materials, depending on the theory used for the prediction. In general, for both cases, the same type of characterization is required for tensile and fracture toughness, and the accuracy of the prediction depends on the crack size and angle [3], [1], [2].

References

[1] A. Zolfagharian, M. R. Khosravani, and A. Kaynak, “Fracture Resistance Analysis of 3D-Printed Polymers,” Polymers (Basel)., vol. 12, no. 2, p. 302, Feb. 2020.

[2] M. R. Khosravani and A. Zolfagharian, “Fracture and load-carrying capacity of 3D-printed cracked components,” Extrem. Mech. Lett., vol. 37, p. 100692, 2020.

[3] B. Ameri, F. Taheri-Behrooz, and M. R. M. Aliha, “Fracture loads prediction of the modified 3D-printed ABS specimens under mixed-mode I/II loading,” Eng. Fract. Mech., vol. 235, p. 107181, 2020.