Dynamic Failure Theory

The following is a summary of codified guidelines for failure theory (TEFA) based on the analysis of the accuracy and requirements of models used to predict the failure of materials manufactured by FFF or FDM, highlighting in bold the accuracy of the models as a measure of the degree of reliability of the products.

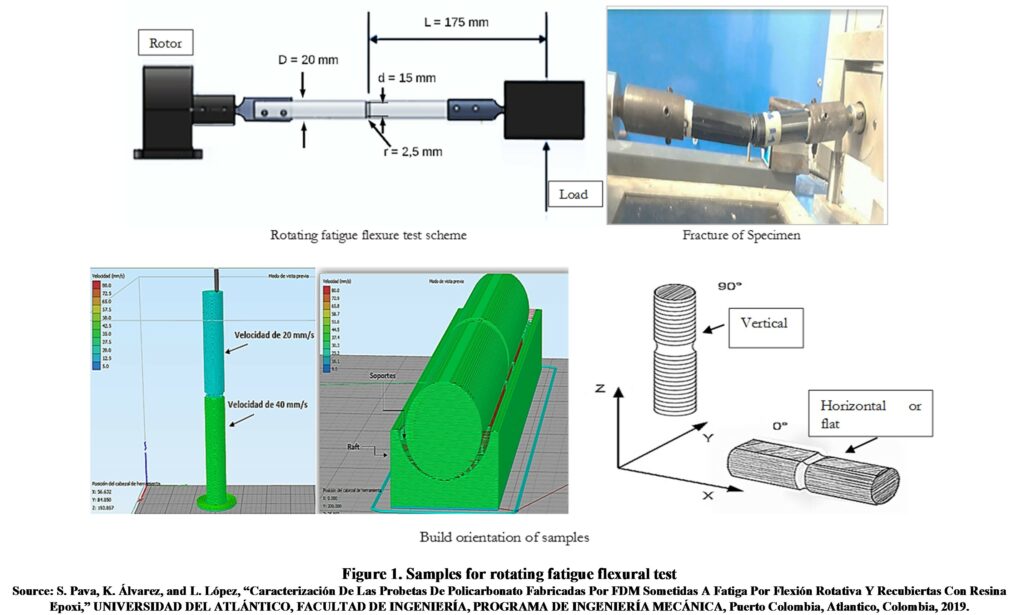

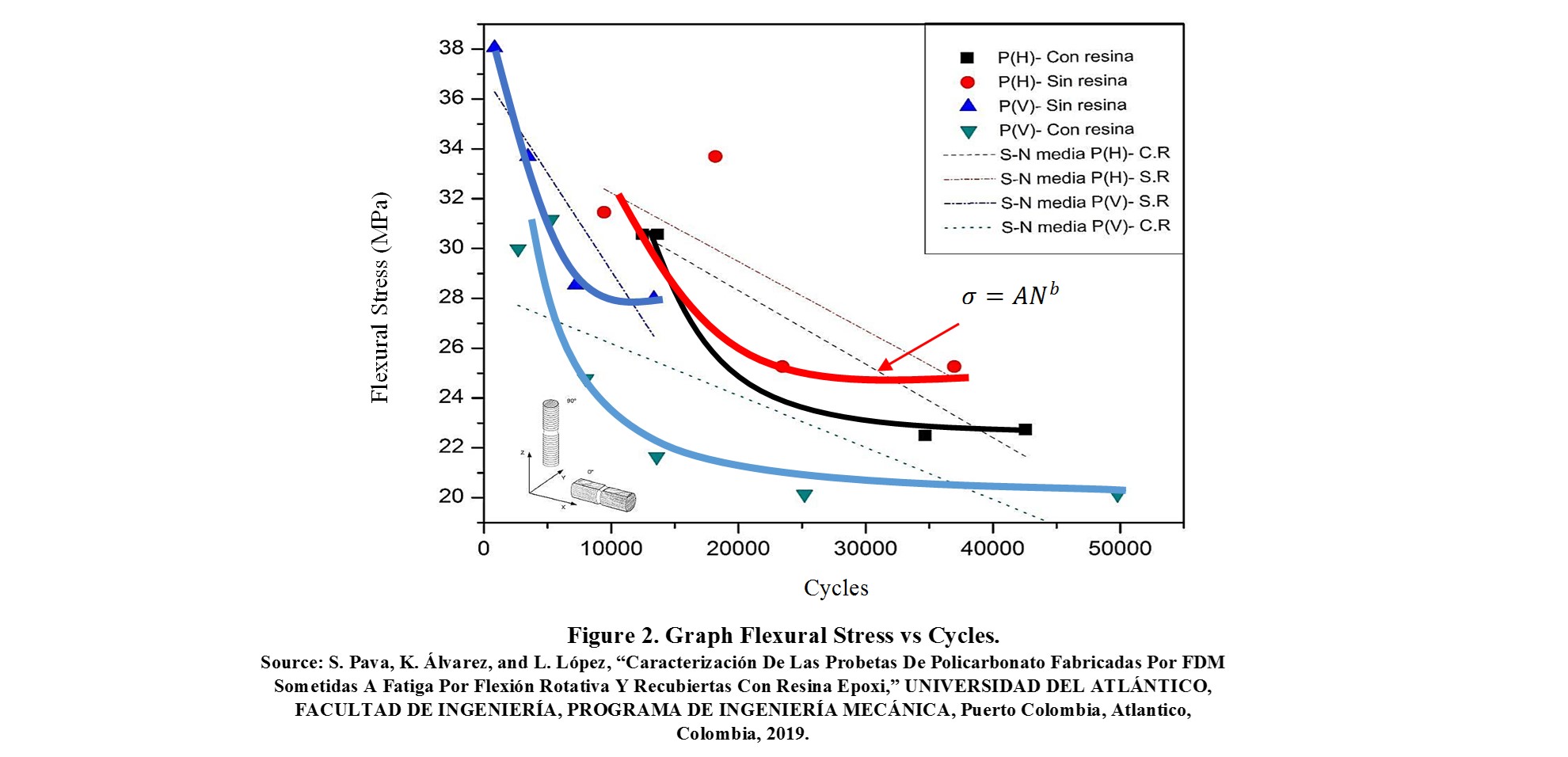

TEFA-11. The life of parts subjected to dynamic loading can be predicted by previous fatigue characterization in different orientations and using the modified Goodman model (see Figure 1) [1] and the potential stress equation as a function of life (see Figure 2) [2]

The average errors range from 10% to 30% depending on the specific orientation and load level, with higher dispersion for vertical orientation and low load (20% of the tensile strength) [1].

References

[1] J. M. Puigoriol-Forcada, A. Alsina, A. G. Salazar-Mart\’\in, G. Gomez-Gras, and M. A. Pérez, “Flexural fatigue properties of polycarbonate fused-deposition modelling specimens,” Mater. Des., vol. 155, pp. 414–421, Oct. 2018.

[2] S. Pava, K. Álvarez, and L. López, “Caracterización De Las Probetas De Policarbonato Fabricadas Por FDM Sometidas A Fatiga Por Flexión Rotativa Y Recubiertas Con Resina Epoxi,” UNIVERSIDAD DEL ATLÁNTICO, FACULTAD DE INGENIERÍA, PROGRAMA DE INGENIERÍA MECÁNICA, Puerto Colombia, Atlantico, Colombia, 2019.