Disadvantages and other recommendations for Process Chain with FFF

The guidelines have disadvantages that, in turn, lead to other recommendations, some of which are presented below.

RG-CP-09. If considering using non-commercial filament materials in the specific design, contemplate setting up an extrusion and raw material manufacturing process for FFF and evaluate the impact on cost and time.

RG-CP-10. If considering consolidating printed parts, keep in mind that each method involves designing the specific joint, depending on the type of process.

Consider among the consolidation methods the following: Hot air welding, adhesive consolidation, standardized joint (bolt and nut), form or press fit joint, and combined joint (e.g., form and adhesive).

RG-CP-11. If considering additional processes and materials, remember that these increase costs, post-processing time, and personnel required.

Depending on the materials, negative environmental and health impacts may also increase. Consider these aspects and quantify them before deciding.

RG-CP-12. Considering the process chain, consider that applying design rules for manufacturing with conventional processes limits the freedom of the FFF shape depending on the conventional processes.

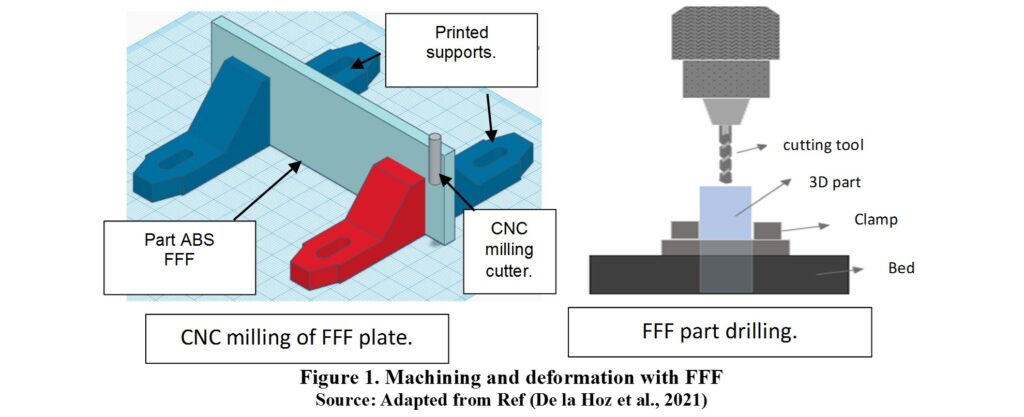

For example, if combined with machining, ensure the part has an adequate clamping mode for the cutting machine after printing (see Figure 1).

RG-CP-13. Depending on the conventional process to be combined, the expected result from the interrelation of the printed process parameters with the conventional process parameters, which explains the wide ranges in the data base. Consider restrictions specific to each process, for example:

- in the acetone vapor smoothing process, the best finish is obtained for parts manufactured vertically with specific bath times.

- if the part is combined with machining, it must be ensured that it has sufficient perimeter solid layers to prevent the cutting tool from reaching the internal finish of the part, which has a poor finish.

- Even if the printed part has a sufficient solid thickness, the optimum finish, when combined with machining, occurs with a specific combination of thickness, manufacturing orientation, and machining angle.