Design rules for FFF

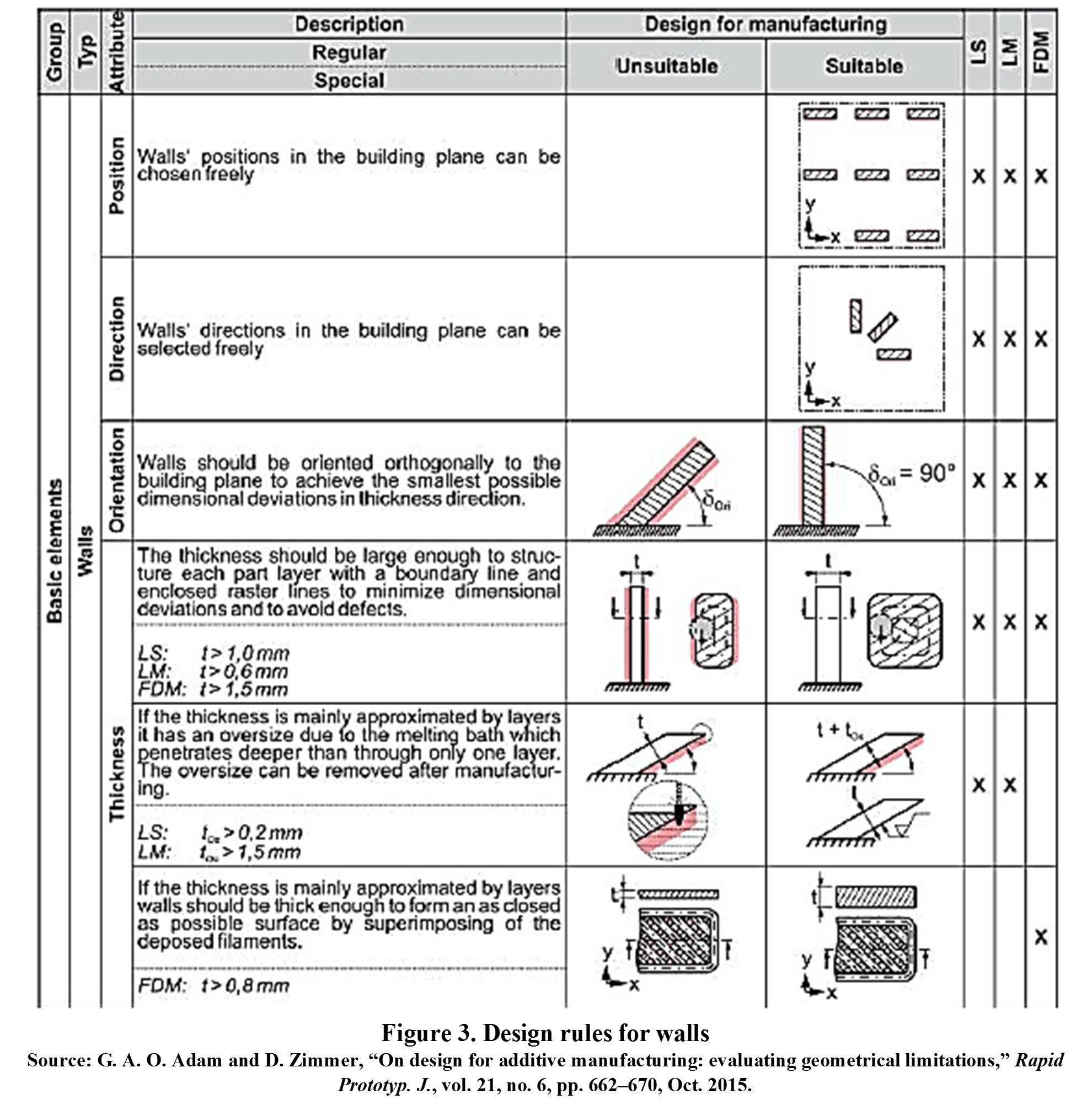

This page presents basic design rules for FFF by specific process parameters. Table 1 shows the basic design rules for FFF.

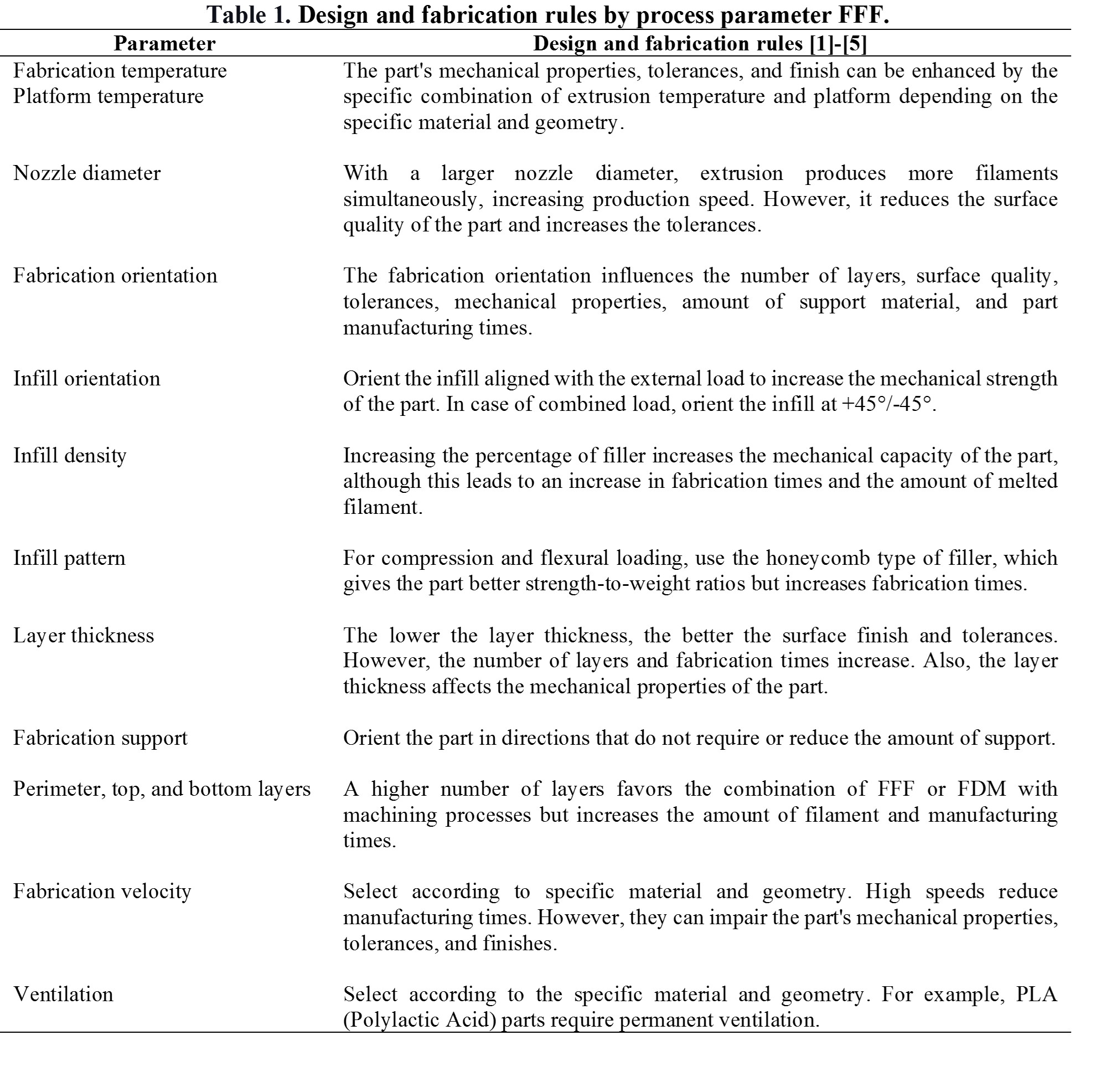

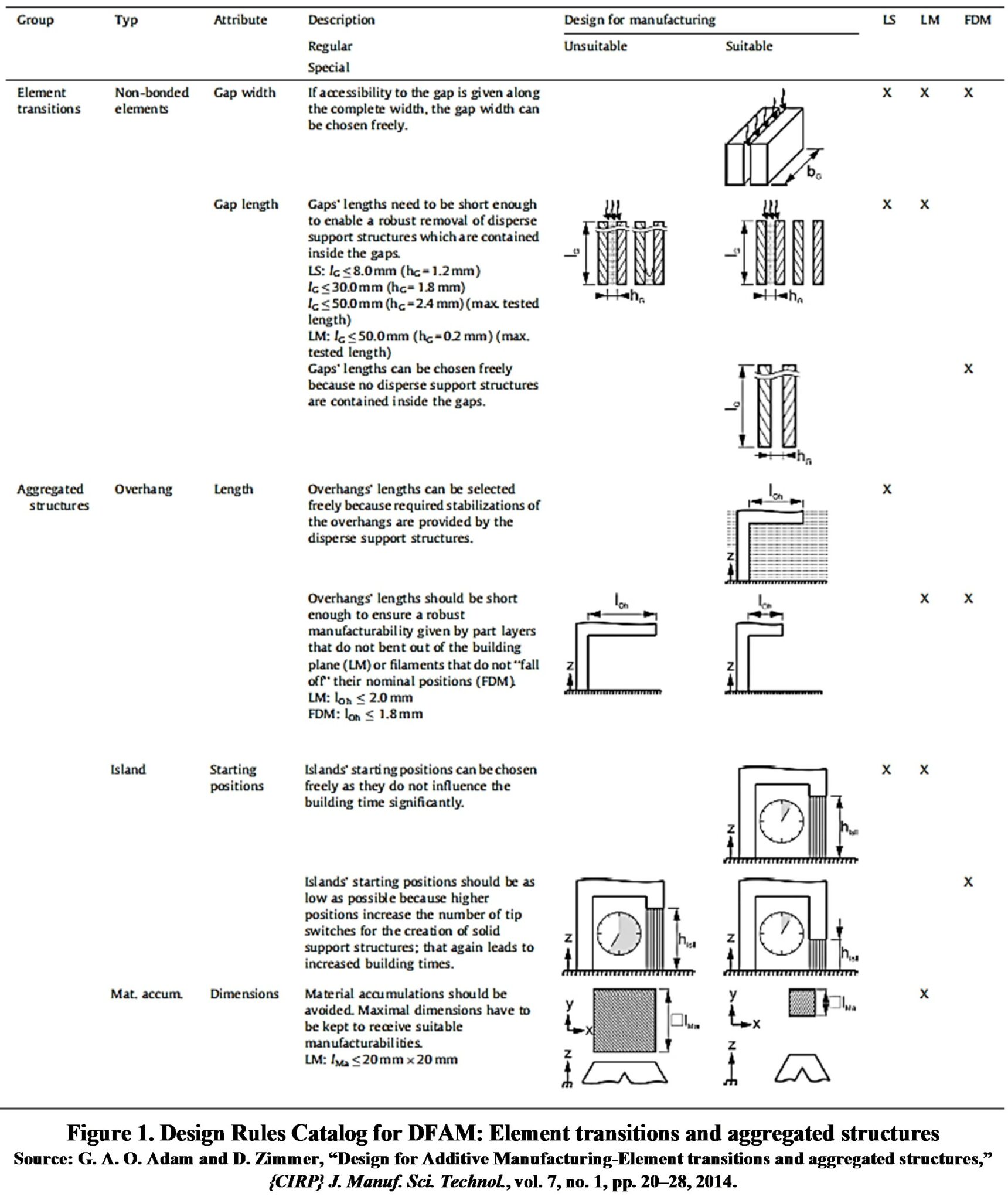

Figures 1-2 are from a design catalog developed by G. A. O. Adam and D. Zimmer [6], which provides recommendations regarding element transitions, aggregate structure, and process limits.

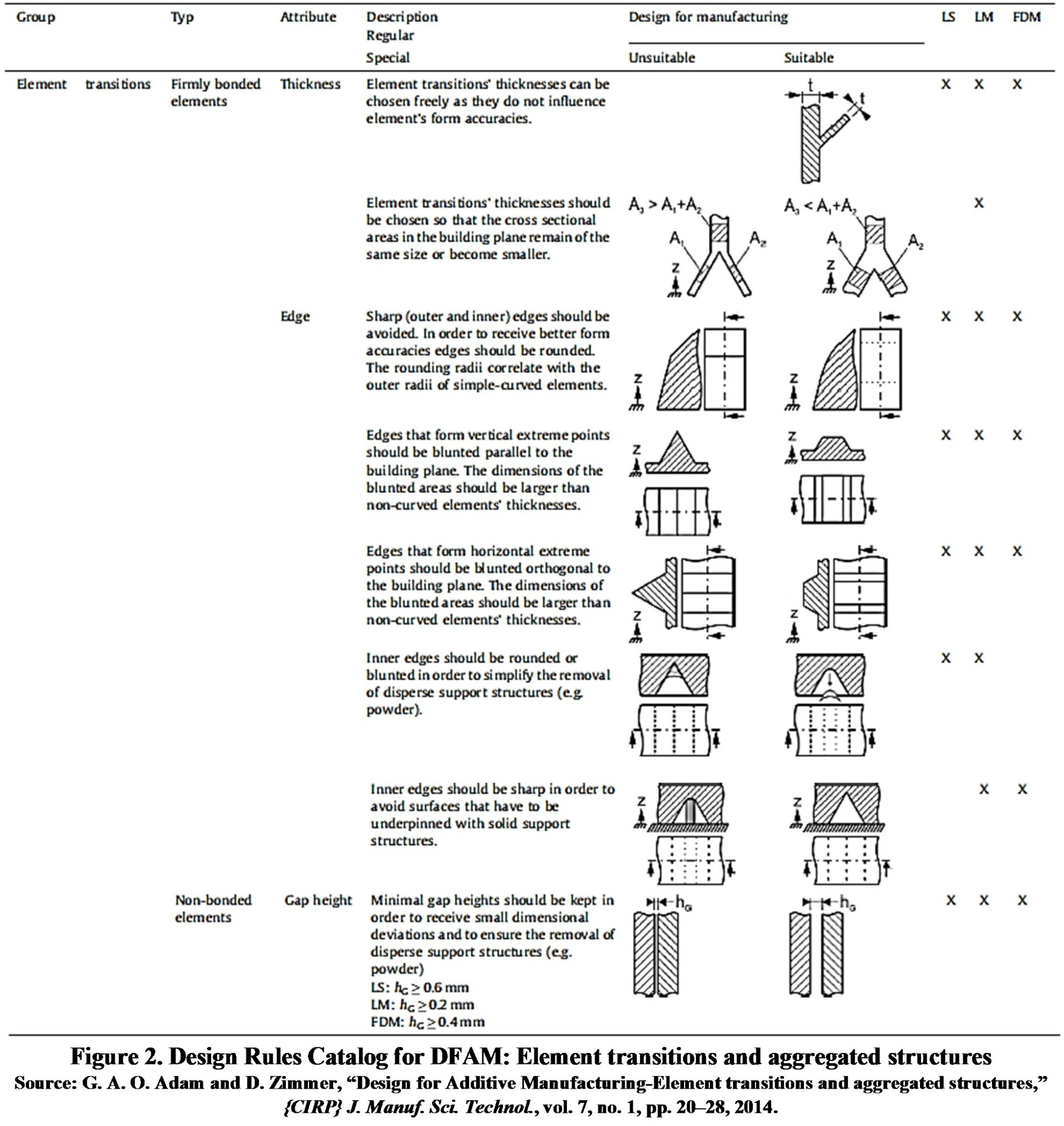

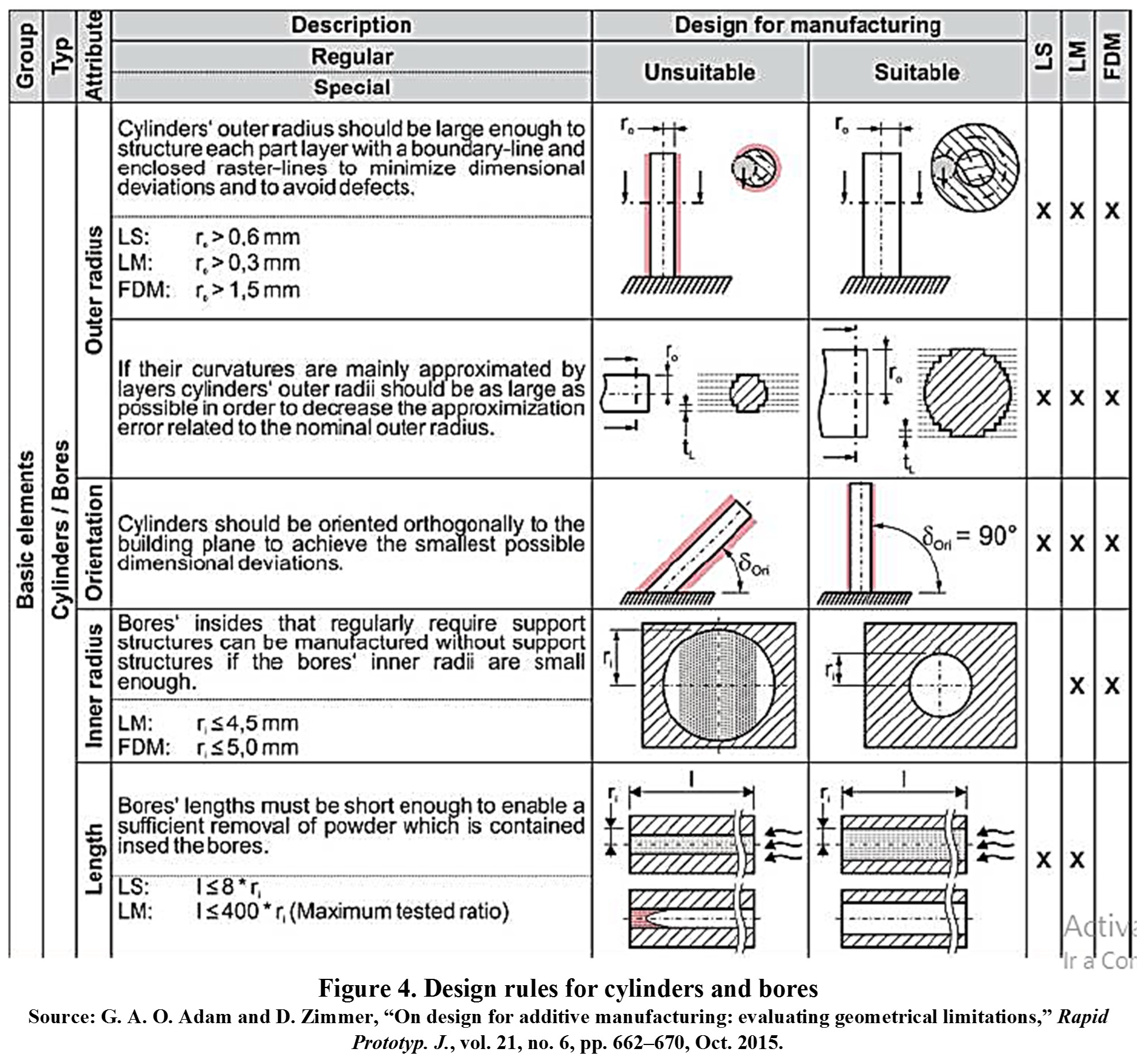

Along the same lines, Figures 3-4 [7] guide the walls, printed cylinders, and bores and their process limits.

On the other hand, design cards have been developed for additive manufacturing [8]-[9], that consider aspects such as Process Capabilities, Manufacturability Improvements, Best Known Design Practices, and Design Process Improvements. The following are the design cards (source [8]).

AM Principle Cards

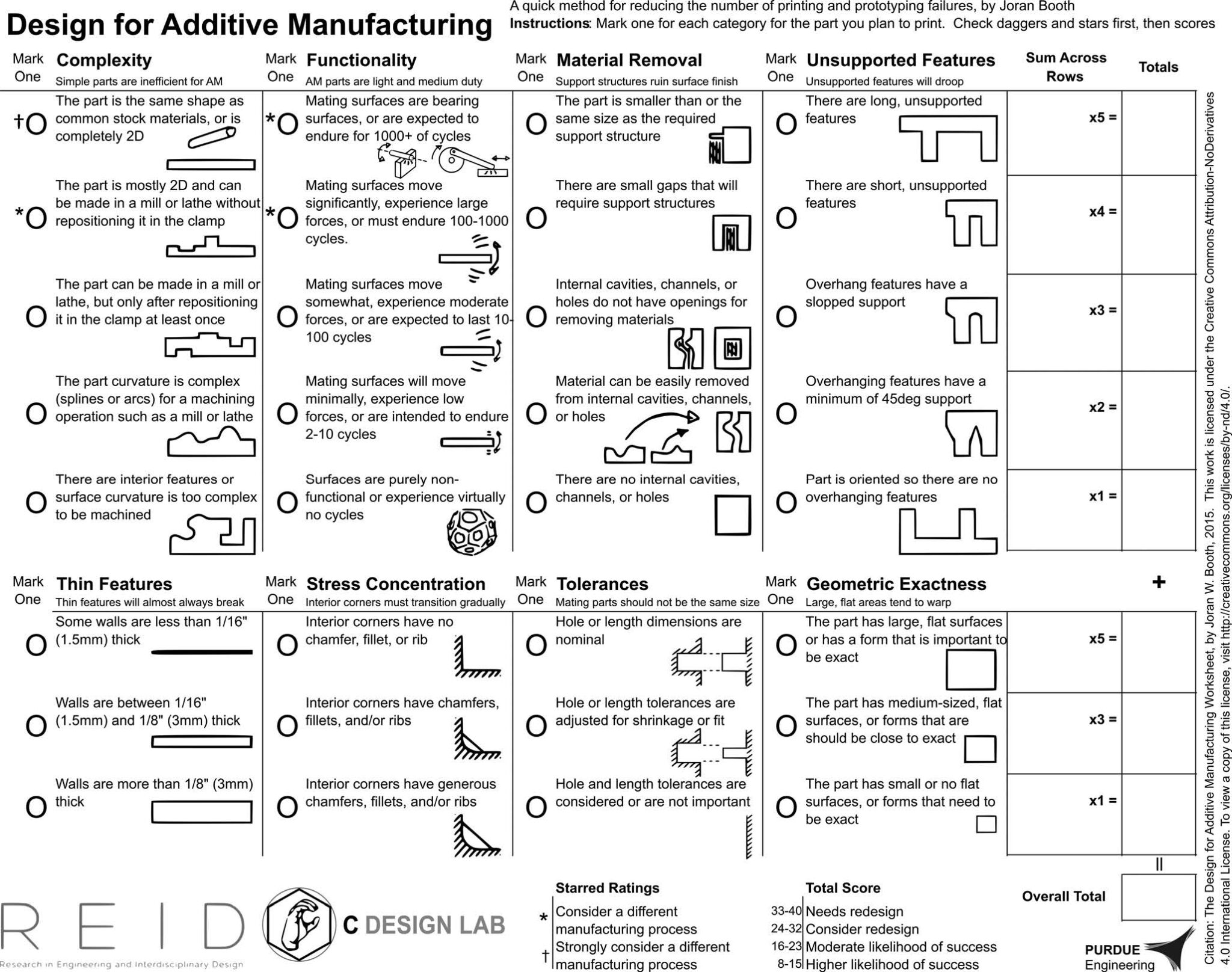

In addition, J. W. Booth et al. [10] developed a worksheet to tell whether a part is manufactured by additive or conventional manufacturing. The worksheet, presented in Figure 5 below, serves as design guidelines or rules.

It is recommended that the information in the medical, process chain, and fault theory case pages be used to push the natural limits of the FFF process to take advantage of its virtues [3]-[5].

References

[1] H. I. Medellin-Castillo and J. Zaragoza-Siqueiros, “Design and Manufacturing Strategies for Fused Deposition Modelling in Additive Manufacturing: A Review,” Chinese J. Mech. Eng., vol. 32, no. 1, Jun. 2019.

[2] ASTM, “ASTM F3529-1: Guide for Additive Manufacturing — Design — Material Extrusion of Polymers.” p. 22, 2022.

[3] Luis Lisandro Lopez Taborda et al, Design methodology for Fused Filament Fabrication for medical and personalization applications: framework, Knowledge base/database, methodology, Universidad del Atlántico, Universidad del Norte, 3D Ingenieria BQ SAS, Barranquilla, Colombia, 2024.

[4] Luis Lisandro Lopez Taborda et al. Design methodology for Fused Filament Fabrication with process chain: framework, Knowledge base/database, methodology. Universidad del Atlántico, Universidad del Norte, 3D Ingenieria BQ SAS, Barranquilla, Colombia, 2024.

[5] Luis Lisandro Lopez Taborda et al. Design methodology for Fused Filament Fabrication with failure theory: framework, knowledge base/ database, methodology. Universidad del Atlantico, Universidad del Norte, 3D Ingenieria BQ SAS, Barranquilla, Colombia, 2024

[6] G. A. O. Adam and D. Zimmer, “Design for Additive Manufacturing{\textemdash}Element transitions and aggregated structures,” {CIRP} J. Manuf. Sci. Technol., vol. 7, no. 1, pp. 20–28, 2014.

[7] G. A. O. Adam and D. Zimmer, “On design for additive manufacturing: evaluating geometrical limitations,” Rapid Prototyp. J., vol. 21, no. 6, pp. 662–670, Oct. 2015.

[8] C. A. Lauff, K. B. Perez, B. A. Camburn, and K. L. Wood, “Design Principle Cards: Toolset to Support Innovations With Additive Manufacturing,” in Volume 4: 24th Design for Manufacturing and the Life Cycle Conference$\mathsemicolon$ 13th International Conference on Micro- and Nanosystems, 2019.

[9] A. Blösch-Paidosh, S. Ahmed-Kristensen, and K. Shea, “Evaluating the Potential of Design for Additive Manufacturing Heuristic Cards to Stimulate Novel Product Redesigns,” in Volume 2A: 45th Design Automation Conference, 2019.

[10] J. W. Booth, J. Alperovich, P. Chawla, J. Ma, T. N. Reid, and K. Ramani, “The Design for Additive Manufacturing Worksheet,” J. Mech. Des., vol. 139, no. 10, p. 100904, 2017.