Cases and findings for FFF with Failure Theory

Failure theory refers to the models that relate the stresses produced by external loads to the part with the mechanical properties of the material to predict whether the part will suffer affection or damage. Additionally, the correct use of failure theory helps fulfill part function without damage.

Moreover, the damage is the permanent deformation of the part, fragmentation, or reaching a prescribed deformation value.

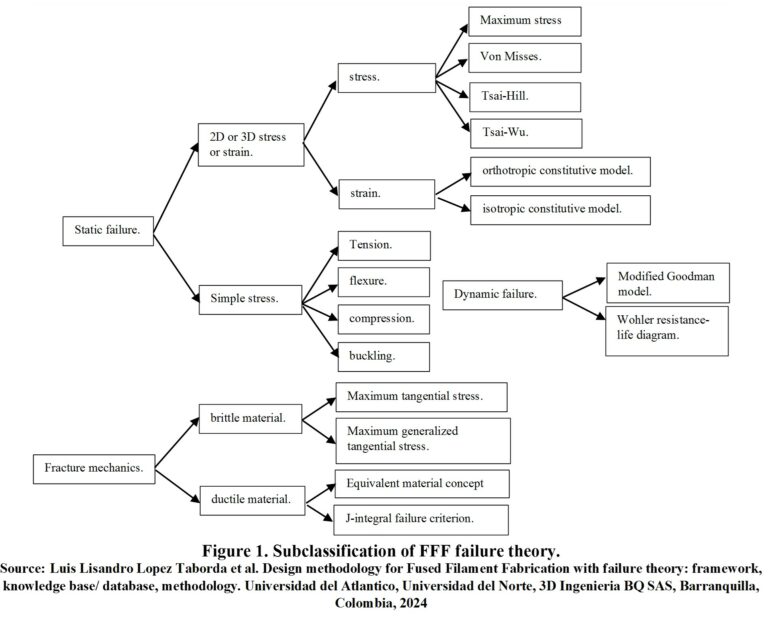

Figure 1 summarizes the subclass of models that predict the failure of materials manufactured by FFF/FDM [1].

The following is a summary of codified guidelines for failure theory (TEFA) based on the analysis of the accuracy and requirements of models used to predict the failure of materials manufactured by FFF or FDM, highlighting in bold the accuracy of the models as a measure of the degree of reliability of the products [1].

References

[1] Luis Lisandro Lopez Taborda et al. Design methodology for Fused Filament Fabrication with failure theory: framework, knowledge base/ database, methodology. Universidad del Atlantico, Universidad del Norte, 3D Ingenieria BQ SAS, Barranquilla, Colombia, 2024