Mechanical Strength

Here are the summarized general rules (RG) of design, categorized by common topics. The competitive and innovative advantages are highlighted in bold, and their application is illustrated with Figures or Tables.

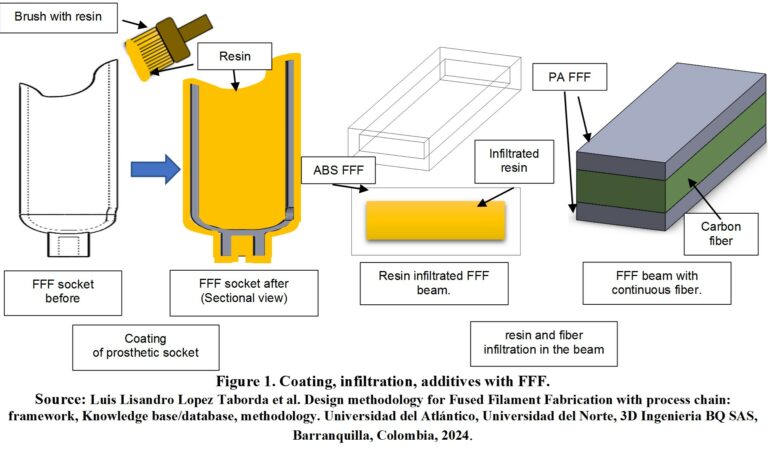

RG-CP-06. To improve the strength, combine with coatings, infiltration, or continuous or discontinuous fiber attachments. Consider also annealing but in crystalline materials.

Figure 1 showcases resin application on a prosthetic socket, enhancing its appearance with a smooth, glossy finish.

Figure 1 on the right and left are coated and infiltrated with epoxy resin, prosthetic sockets, and printed beams to improve their interlaminar and flexural strength. Continuous and discontinuous fiber attachments are effective to increase the strength in the strongest fabrication orientation.

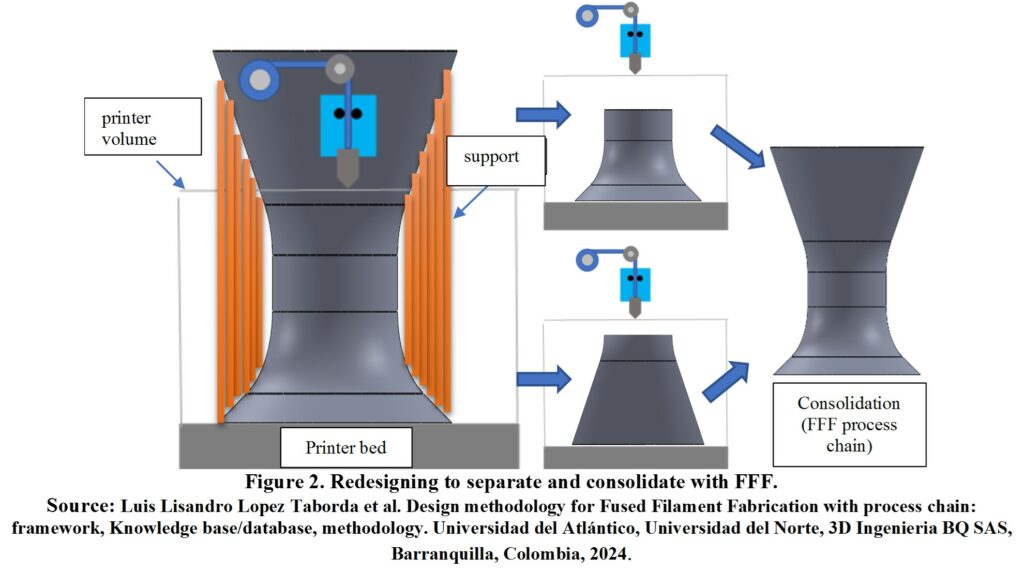

RG-CP-07. To improve the strength, redesign a consolidated part into an assembly of several subsequently consolidated or unconsolidated parts. Consider the following possibilities:

- FFF manufactures different parts of a single material but with different process parameters, such as orientation, and filler percentage, among others.

- parts of different materials processed by FFF, with different process parameters each.

- parts of different materials processed by FFF and other processes.

Figure 2 on the left side demonstrates a case where the part’s size exceeds the available printer capacity, necessitating support material and resulting in increased material consumption and longer manufacturing times.

Figure 2 presents an example aimed at improving the production and finishing rate and breaking the limitations of the maximum manufacturing volume. However, in this case, although the strategy is similar, the focus is to consider the mechanical strength of the part and to reconsider printing orientation with the most robust mechanical strength for separation, fabrication, and consolidation in the end.

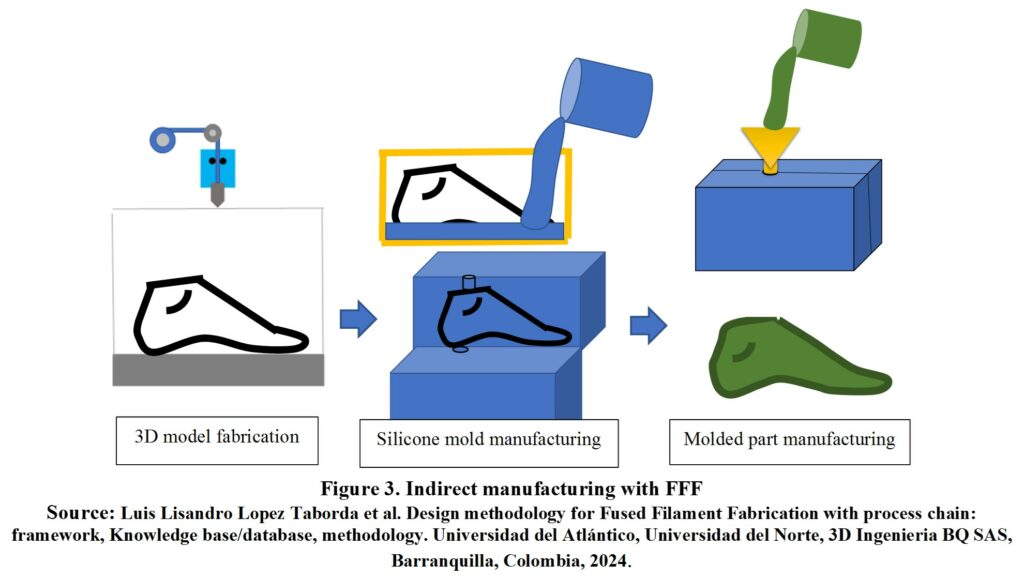

RG-CP-08. Manufacturing indirectly with FFF to support other processes with better mechanical strength: plastic injection, blow molding, hydroforming, and thermoforming.

Figure 3 illustrates the manufacturing of prosthetic foot.

An example of the guideline was presented in Figure 3, but now, mechanical strength is considered, like a material more robust or flexible than is possible with FFF directly.