DF-FFF for ME&P

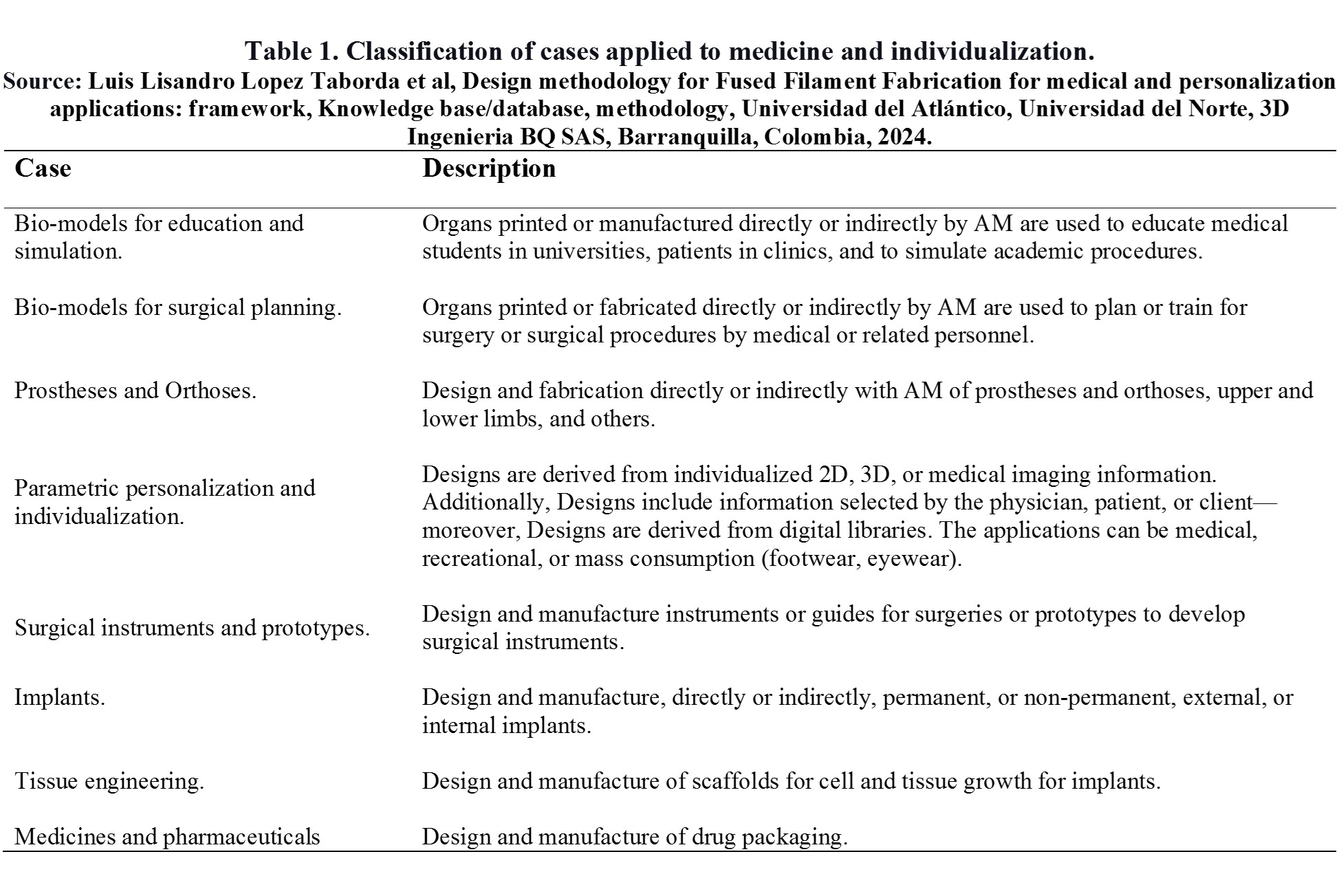

Table 1 summarizes the classification and description of the cases applied to medicine and individualization found during the documentary review’s analysis.

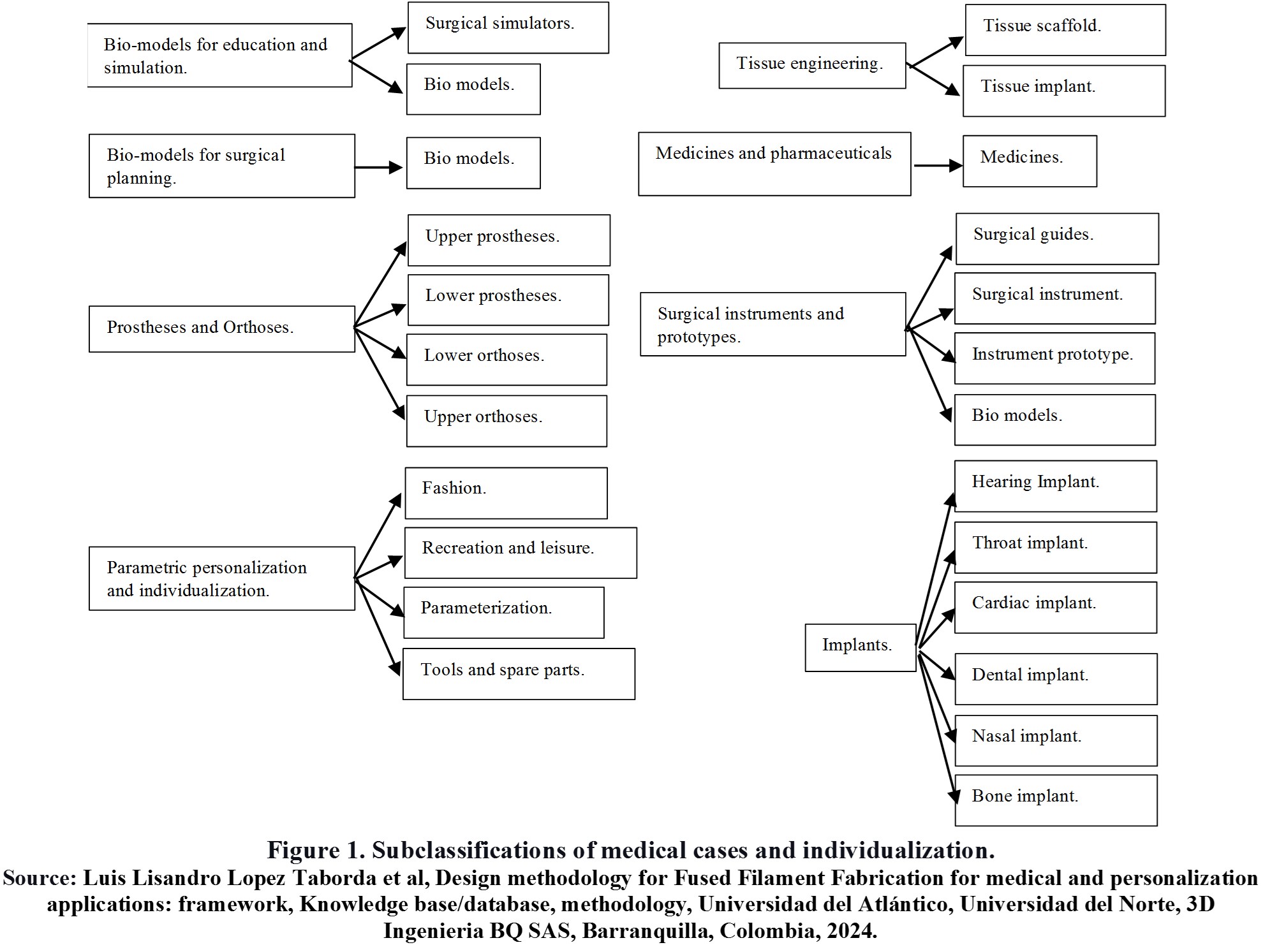

Figure 1 summarizes the medical case subclassifications and individualization that were obtained.

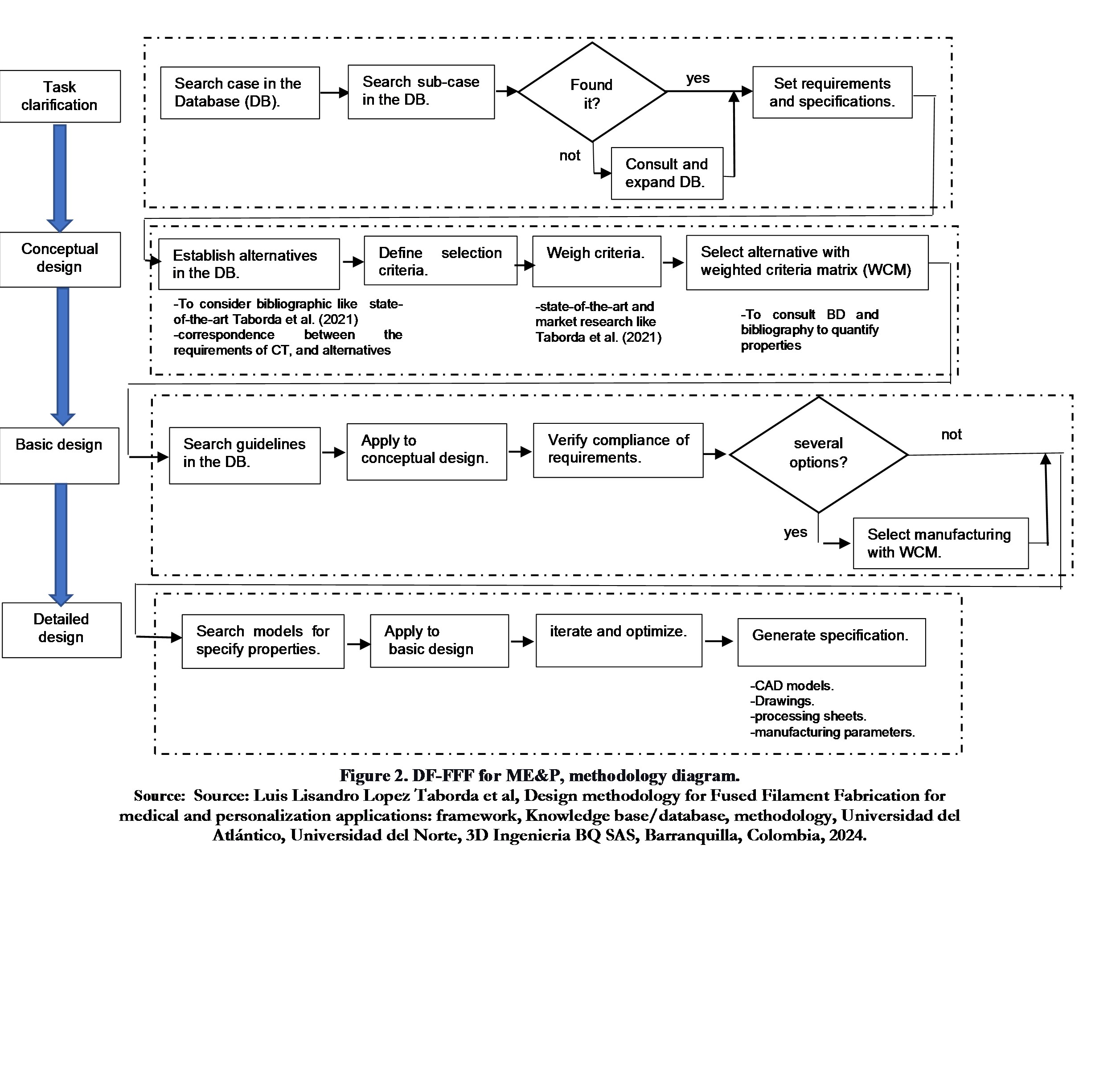

Figure 2 summarizes the general DF-FFF methodology for ME&P.

The following [6] explains the steps in Figure 2 grouped by each design phase.

Task clarification (TC). At the end of this phase, the lists of requirements, criteria, or specifications/properties of the product to be developed will be obtained. For this purpose, the following steps must be followed:

a)Search within the database (DB) for the general case to which the product to be designed (see Table 1)

b)The specific case is searched (see Figure 1)

c)If the specific or similar product is not found in the DB, it is possible to:

- Search in the specialized bibliography.

- Analyze the references that coincide with the product.

- Define the product requirements and specifications for each reference

- Feedback of the DB.

d)Once a DB case matching the desired product is found, the list of requirements is displayed with the specifications defined for the DB case, and based on these, the product is defined for its own product.

Conceptual Design (CD). At the end of this phase, several initial CD will be obtained, and the selection of one or more will be based on requirements or criteria. For this purpose, the following steps should be followed:

a)Establish alternatives and quantitative characteristics per criterion using the DB.

- To consider bibliographic like state-of-the-art and market research like Taborda, Maury and Pacheco [1]

- Look for correspondence between the requirements, specifications, and alternatives to ensure compliance with requirements of the CT phase.

b)Define selection criteria based on the requirements and specifications set in the CT phase.

c)Assign a weighting to the criteria obtained in this phase based on the objectives pursued, market statistics, and quantitative figures.

- For example, state-of-the-art and market research like Taborda, Maury and Pacheco [1].

d)Evaluate and select the alternative using the weighted criteria matrix (WCM) method.

- In this phase, the consultation of the BD and specialized bibliography is used to quantify properties to evaluate and select the best alternative based on objective variables.

Basic Design (BD). At the end of this phase, the BD of the product will be obtained, that is, the rules and process to modify the DC, the modified DC to a shape close to the final shape, and the specific manufacturing process to be used. To this end, the following steps must be followed:

a)Search for the most suitable design rules.

b)Analyze and study the rules or methods by consulting the original references (framework) and apply them to the CD to transform the concept to a basic form according to the requirements.

c)Verify the level of concordance between the primary forms and the requirements and use the DB and the specialized bibliography to quantify properties and features as support.

d)If different basic processing and design forms were generated accordingly, based on properties and requirements, a WCM evaluation would be required to select the BD and its processing form.

Design in Detail (DD). At the end of this phase, the final digital model and the specifications and process parameters will be obtained. For this purpose, the following steps must be followed:

a)In the DB and specialized bibliography, search for the information, model, or program that helps to specify the product property.

b)Appropriate in the use of models or CAD (Computer Aided Design) /CAM (Computer Aided Manufacturing) programs to apply to DB and transform it into DD.

c)Use the data and models to simulate and modify the design performance until it conforms to the requirements through an iterative process. Use WCM in the most demanding cases.

d)Generate design specifications by exporting:

- CAD models.

- Drawings

- processing sheets.

- manufacturing parameters.

The selected method is chosen for its simplicity, reliability, and integration of proven tools from conventional design theory (CDT) [2]–[5] like requirements listing, WCM, and direct search method. These methods were selected for their known effectiveness and practicality. The comprehensive nature of the methodology aims to cover all design phases, with each phase utilizing appropriate tools from CDT.

However, a major challenge lies in the development of design rules for multiple cases to structure existing guidelines for efficient searching in the necessary database for method implementation. To this end, the specific and general rules and cases & findings of this work were deduced and constructed, and the information analyzed structured the DB.

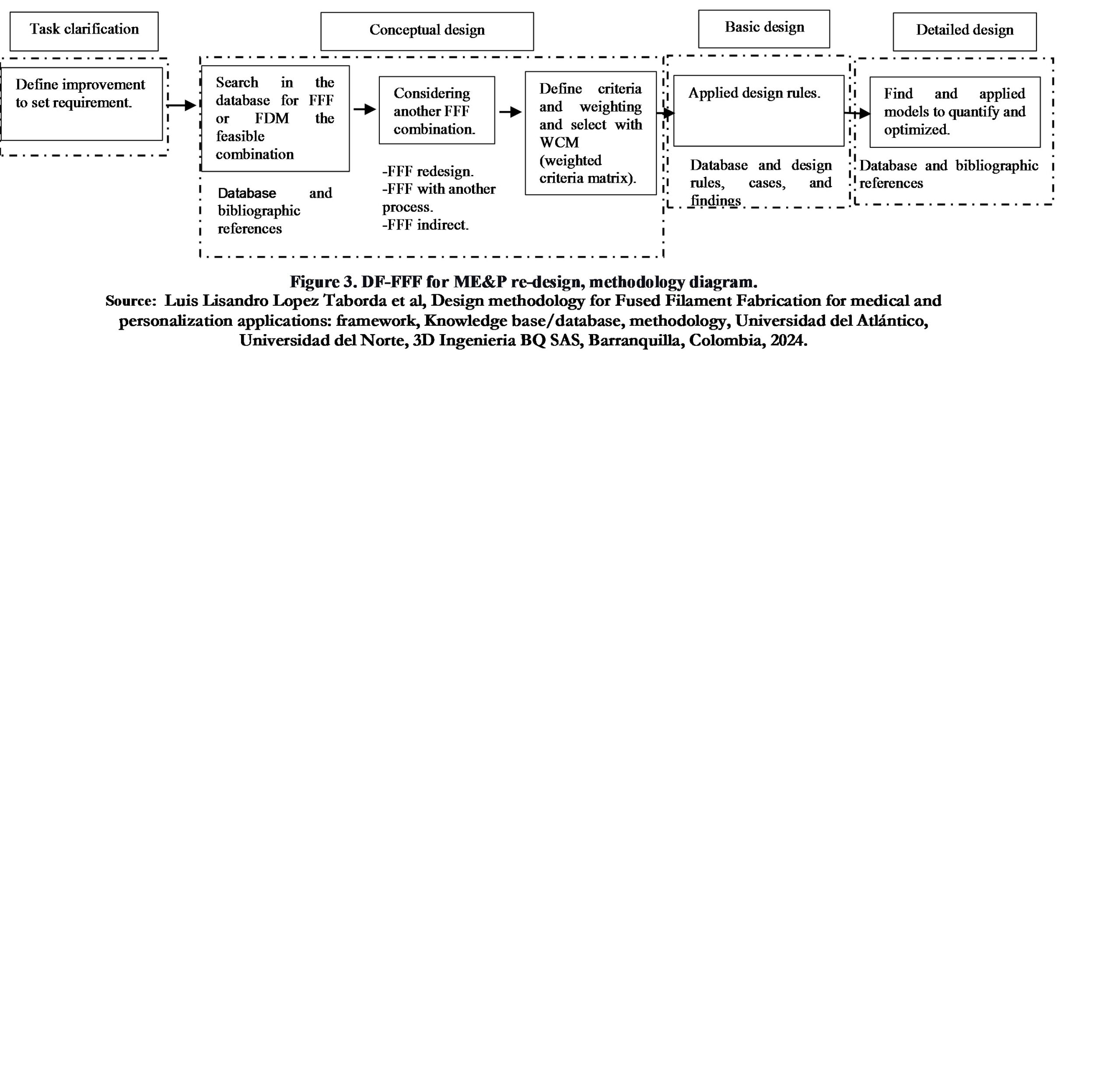

The case study focuses on redesigning parts to either meet specific requirements or enhance performance, as outlined in Figure 3.

- Identify the improvement percentage needed for the part to meet requirements.

- Search the database for suitable materials and printing conditions.

- Evaluate FFF options, including redesign strategies, material-process combinations, and indirect manufacturing methods.

- Select the best alternative using a weighted criteria matrix.

- Consult process parameters for FFF or FDM as per design rules

- Apply models to quantify and optimize the part using database and bibliographic references.

References

[1] L. L. Lopez Taborda, H. Maury, and J. Pacheco, “Design for additive manufacturing: a comprehensive review of the tendencies and limitations of methodologies,” Rapid Prototyp. J., vol. 27, no. 5, pp. 918–966, Jun. 2021.

[2] G. E. Dieter, L. C. Schmidt, and others, Engineering design. McGraw-Hill Higher Education Boston, 2009.

[3] G. Pahl and W. Beitz, Engineering design: a systematic approach. Springer Science & Business Media, 2013.

[4] D. G. Ullman, The mechanical design process, 4th ed. New York: McGraw-Hill, 2010.

[5] W. A. K. Geoffrey Boothroyd Peter Dewhurst, Product Design for Manufacture and Assembly, Third Edition, Third Edit. CRC Press, 2011.

[6] Luis Lisandro Lopez Taborda et al, Design methodology for Fused Filament Fabrication for medical and personalization applications: framework, Knowledge base/database, methodology, Universidad del Atlántico, Universidad del Norte, 3D Ingenieria BQ SAS, Barranquilla, Colombia, 2024.