Tolerances prediction of FFF parts

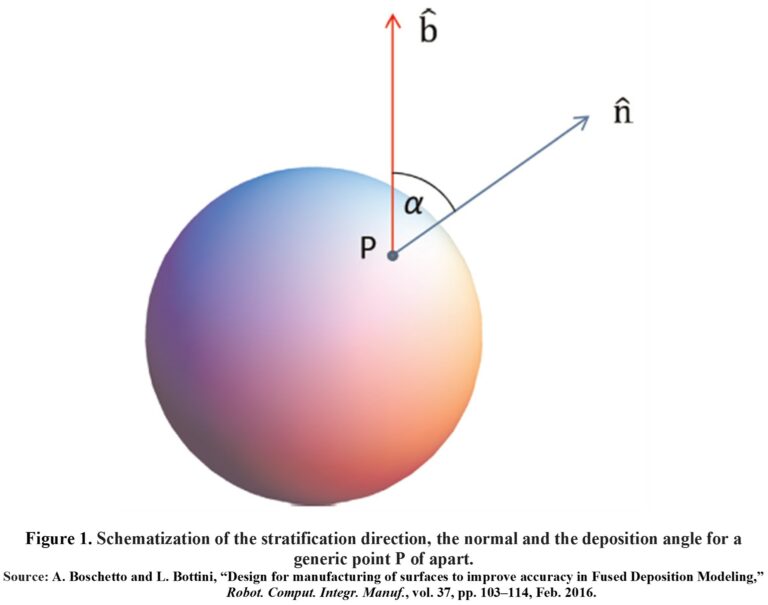

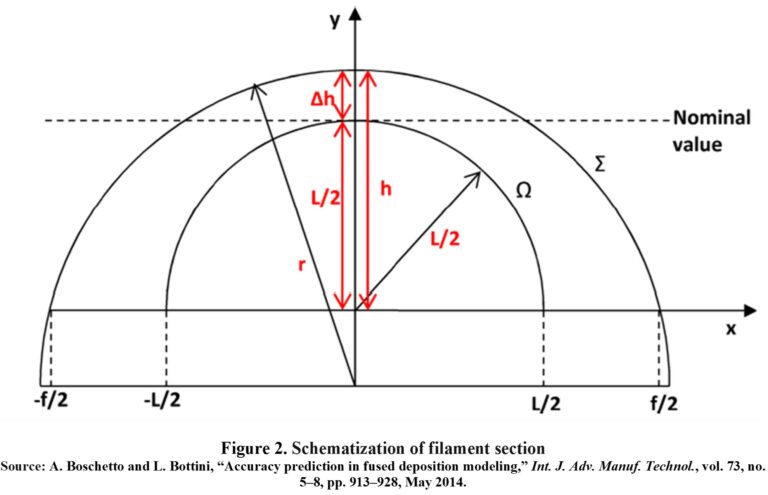

On this page, you can predict the tolerances of the parts to be manufactured by FFF or FDM, depending on manufacturing parameters such as layer height, build orientation, among others. See Figure 1-2 to understand the parameters to be considered and the tolerances to be calculated.

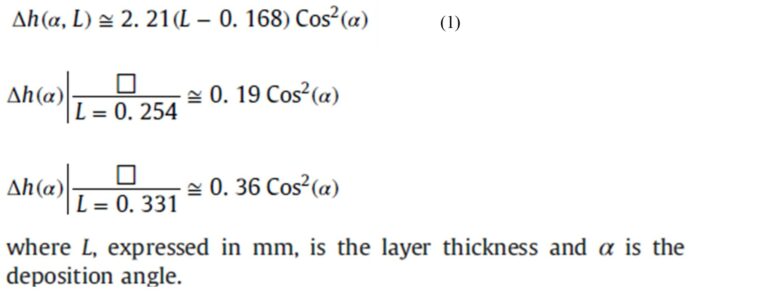

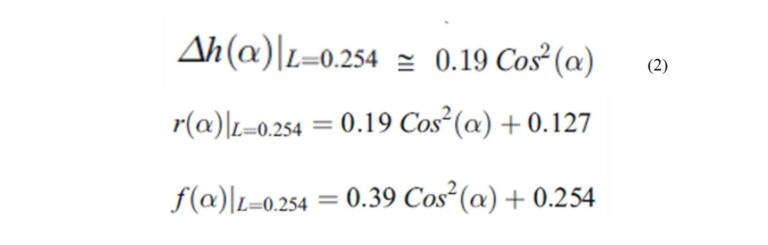

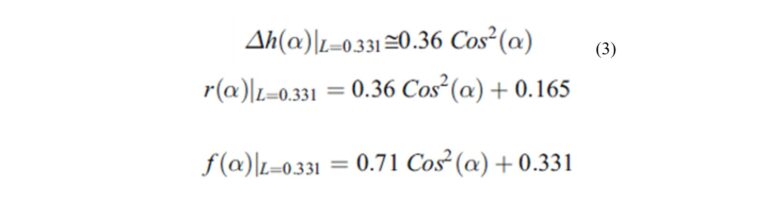

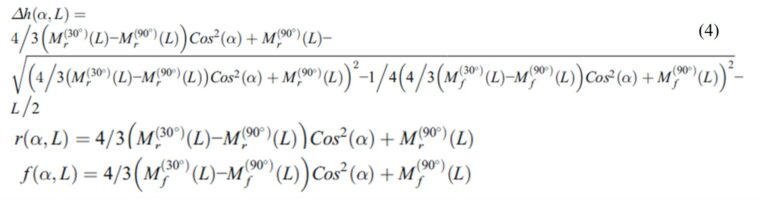

The tolerances is calculated with the equation (1)-(4) (references [1], [2] with references dates [3], [4]) presented below

Then, use the calculated field form by entering the different required parameters and referring to the last row for the tolerance.

Mr and Mf are values of r-radius and f-spacing between filaments, measured at specific angles α indicated of 30° and 90°. Mr and Mf values were taken based on r and f measured in [3] and [4] at layer heights L of 0.254mm and 0.331mm, for FDM systems and ABS material.

References

[1] A. Boschetto and L. Bottini, “Design for manufacturing of surfaces to improve accuracy in Fused Deposition Modeling,” Robot. Comput. Integr. Manuf., vol. 37, pp. 103–114, Feb. 2016.

[2] A. Boschetto and L. Bottini, “Accuracy prediction in fused deposition modeling,” Int. J. Adv. Manuf. Technol., vol. 73, no. 5–8, pp. 913–928, May 2014.

[3] A. De la Hoz, C. Coronado, and L. Lopez, “Estudio Experimental De Los Procesos De Mecanizado Para Mejorar El Acabado Superficial y Tolerancias De Las Piezas Impresas En 3D,” UNIVERSIDAD DEL ATLÁNTICO, FACULTAD DE INGENIERÍA, PROGRAMA DE INGENIERÍA MECÁNICA, Puerto Colombia, Atlantico, Colombia, 2021.

[4] A. Boschetto, V. Giordano, and F. Veniali, “3D roughness profile model in fused deposition modelling,” Rapid Prototyp. J., vol. 19, no. 4, pp. 240–252, Jun. 2013.