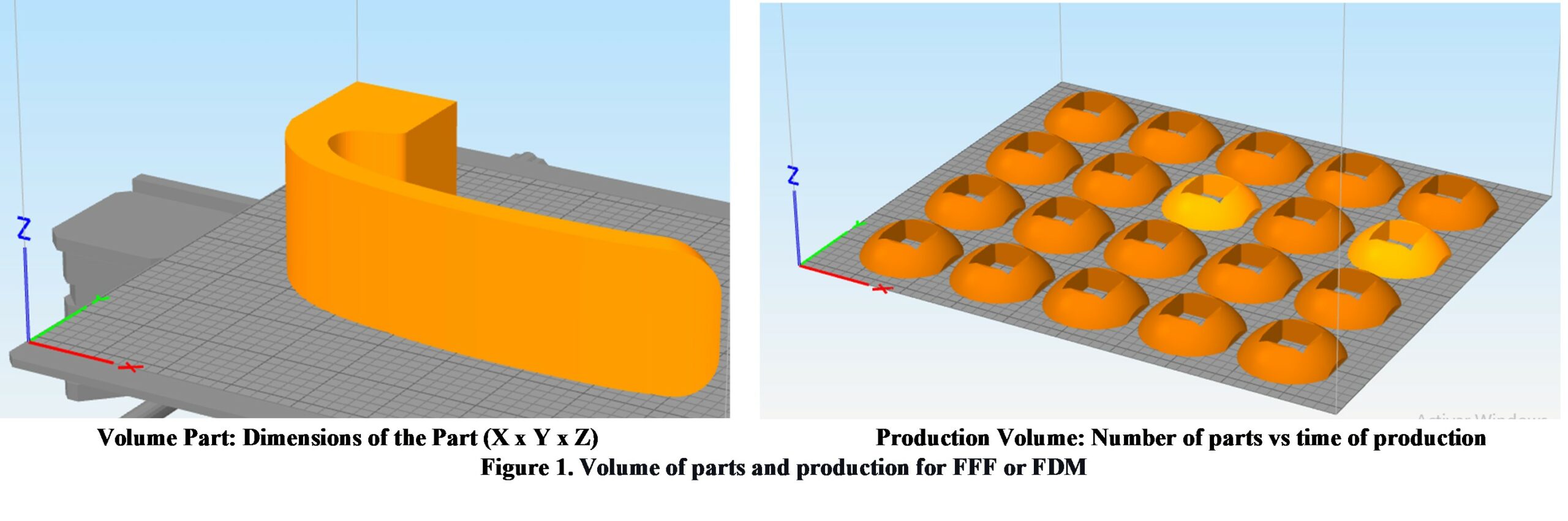

Volume of parts and production

Refer to the largest possible size or dimensions of parts recommended for manufacturing and annual production volumes or production for tooling based on case studies, surveys, and industry recommendations.

- Less than 1000 parts per year with sizes less than 150×150×50 mm [1].

- One to hundreds, for example, 300 or 600 (up to 1000 units) per year with volumes of 120x 120x120mm, 60x60x50mm, 135x100x38mm) [2].

- Using FDM/FFF for prototyping injection molding tools, hundreds of units to thousands can be used for injection molding [3].

- Using ABS-M30 to manufacture tools for hydroforming, over 100 cycles is a reasonable expectation, and over 400 is possible with sheet materials such as Aluminum 2024-0 [4] and low to moderate (over 5. 000) [5].

- FDM use in reverse casting is best in low-volume applications (quantity in inverse proportion to part size), typically less than 100 parts [6].

It should be noted that although the volume or size of printing is higher than the above-recommended values, the recommendations are based on the experience and concepts of specialists and experienced personnel, referring to competitive and profitable sizes.

For larger sizes, it is recommended to divide the part, consolidate, or assemble it afterward using adhesive, standardized joints, and welding, among other processes. However, you should consult the Process Chain page because additional processes are included in FFF.

References

[1] P. Pradel, Z. Zhu, R. Bibb, and J. Moultrie, “Investigation of design for additive manufacturing in professional design practice,” J. Eng. Des., vol. 29, no. 4–5, pp. 165–200, Mar. 2018.

[2] J. Munguia, C. Riba, and J. Lloveras, “In the search of design for rapid manufacturing strategies to solve functional and geometrical issues for small series production,” in International Conference on Engineering Design ICED, 2007, vol. 7.

[3] Stratasys, “APPLICATION GUIDE: Injection Blow Molding with FDM.” 2015.

[4] Stratasys, “TECHNICAL APPLICATION GUIDE FDM Tooling for Sheet Metal Forming: Hydroforming and Rubber Pad Press.” 2015.

[5] Stratasys, “TECHNICAL APPLICATION GUIDE: FDM FOR SAND CASTING.” 2013.

[6] Stratasys, “TECHNICAL APPLICATION GUIDE: Investment Casting with FDM Patterns.” 2015.