¿How is DF-FFF made up?

In summary, DF-FFF was created from the elaboration of the state-of-the-art design methodologies for additive manufacturing (DFAM) [1]; after finding limitations and strengths in the methodologies, a new design methodology with particular characteristics was proposed: It includes the use of Fused Filament Fabrication (FFF) because it is an economical technology that constitutes a competitive advantage; the application to cases of medical and personalized products (ME&P) that promotes radical innovation and high added value of the product; the combination with conventional manufacturing processes or process chain (CP) to improve the natural limitations of the FFF process; and the combined use of failure theory (TEFA) to improve and guarantee the mechanical reliability of the products designed with the methodology.

Consequently, DF-FFF has a portion dedicated to the generalities and limitations of the process, i.e., the DF-FFF page. On the other hand, it is made up of three other parts which are:

1- DF-FFF for ME&P (page called “Medical & personalization“) is dedicated to designing medical and customized products.

2- DF-FFF with CP (page called “Process Chain“), which combines FFF with conventional manufacturing processes.

3- DF-FFF with TEFA (page called “Failure theory“) that applies failure theories and process characterizations to guarantee the reliability of products with high mechanical performance.

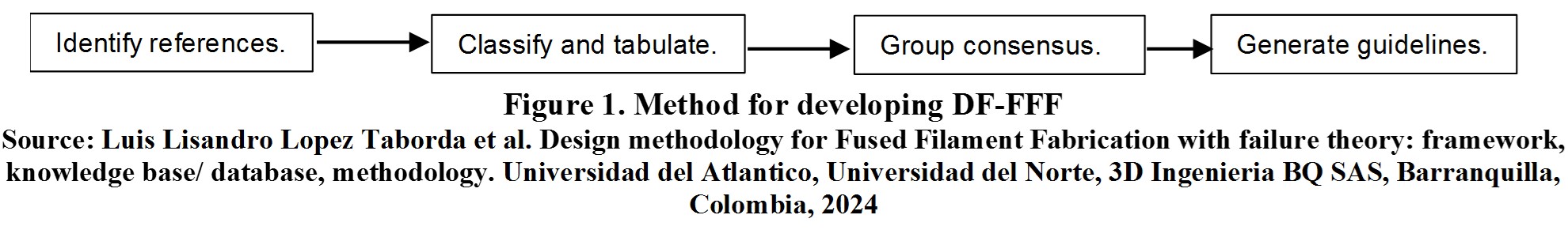

In general, the process shown in Figure 1 was followed to develop the new DF-FFF methodology.

Each step is explained below with its respective justifications:

- References containing failure models for FFF or FDM are identified to ensure the applicability of FFF materials and technology consistent with the overall research objective. The starting point is the database of the combination of FFF with failure theory from the bibliographic research [1].

- It is classified and tabulated in general by Topic.

- The consensus is summarized and grouped by Topic and elevated to guidelines.

References

[1] L. L. Lopez Taborda, H. Maury, and J. Pacheco, “Design for additive manufacturing: a comprehensive review of the tendencies and limitations of methodologies,” Rapid Prototyp. J., vol. 27, no. 5, pp. 918–966, Jun. 2021.